Ecomax 4C rounds off Elster Kromschröder’s self-recuperative burners

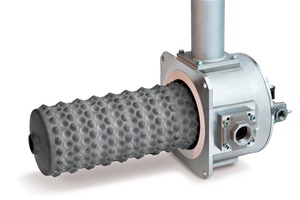

All Ecomax burners have an integrated heat exchanger using the exhaust heat to preheat the combustion air to a maximum of 700° C. Fields of application for the self-recuperative burners are indirect heating systems with radiant tubes or direct heating systems in conjunction with an eductor for reabsorbing the flue gases by suction. The Ecomax series consists of a total of seven sizes and covers a capacity range from 25 to 500 kW. The self-recuperative burners are available in metallic, all-ceramic or flat tube versions (M, C or FTR). Thus, Ecomax.C has a ceramic recuperator made of SiSiC for a maximum application temperature up to 1 300° C. The cast steel ribbed tube recuperator of the Ecomax.M ensures a maximum efficiency up to 1 150° C. All Ecomax burners feature direct electrical ignition and, depending on the application, are directly ionization-controlled or monitored by a UV sensor. The extremely high flame outlet velocity and On/Off control ensure precise temperature control and accuracy in the furnace.