Equipceramic supplies new bevel-cutter on four sides with travelling wire-holder frame to CC Millas

The length of the clay column can be varied between 1 200 and 1 500 mm, the product size can be easily adjusted and changed. The bricks and pavers are bevelled by means of three sets of brass disks. The base of the bricks can be deburred with disks or knives. The clay column and the cut bricks are shifted on brass sheets in order to reduce friction. A double travelling cutting frame is used.

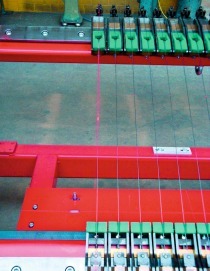

The clay column, already cut into pieces, is shifted into the cutter by a guided PVC belt driven by power-operated equipment. A side pusher lines up and introduces the clay column to the brass cutting table in order to perform the upper and lower bevel. To get the perfect alignment between notches and cutting wires, the bevelling mechanism operates while the clay column is being lifted, just before cutting. Furthermore, the cutting wires slope in order to improve their penetration in the mud. The penetration depth as well as the position of all grooving rolls and knives can be adjusted to adapt to the different bevel sizes and formats. The cutting machine is equipped with an automatic system for cleaning cutting wires and this way, always ensuring a clean cut.

Cut bricks are shifted by means of a pusher to the admission belt where the upper bevel can be applied to obtain the best finish format. As a result, the edges of the product are perfectly bevelled so the unit has the right size to be a quality brick.

One of the main features of this new equipment is the double travelling cutting frame. Thanks to this frame, in case of wire breakages, cutting wires can be automatically changed without stopping the production process.