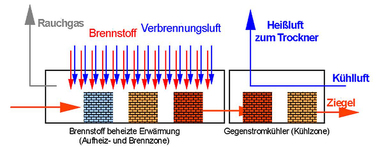

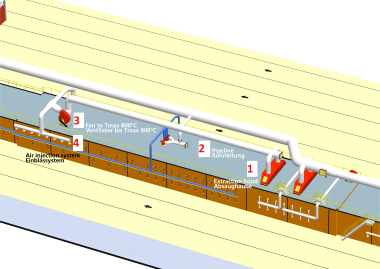

Pulse burners – for uniform kiln-profile quality and lower gas consumption

One of the main requirements for industrial production methods is to turn out products with reproducible physical quality parameters. For ceramic products, the essential parameters are strength, water absorbency, frost resistance, colour, dimensional accuracy, etc. All these physical qualities form and develop during ceramic firing. The firing process is therefore expected to provide reproducible conditions in terms of temperature equilibrium and atmospheric composition. This contribution describes ways and means of achieving these goals.