Reducing energy expenditures for brick production by use of vibrating cutters

Research paper conducted by the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ)Project numberAiF 16074 NProject

funded byBMWi through the German Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF)Implemented byBrick Research Institute Essen Regd (IZF)Project

managersDipl.-Ing. E. Rimpel and Dipl.-Ing.

S. Petereit

1 Background and problem description

To a greater or lesser extent, both phenomena tend to close off the core holes. This impedes the kind of energy-conserving through-air drying that is becoming increasingly popular in modern masonry brickworks. Subsequent grinding of the fired bricks, in turn, presupposes tight dimensional tolerances in order to minimize the required amount of grinding.

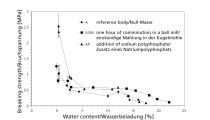

For reasons of energy economy, producers try to use as little batching water as possible for extruding facing bricks. Thus, either less energy has to be expended for evaporating the water, or the freshly extruded brick green bodies can be loaded onto the kiln cars by the “direct setting method”. The force required for cutting stiff-extruded clay columns, however, imposes bottom limits on the reduction of batching water volumes.

2 Procedure

If the blade (wire) is not always pulled in the same direction, but made to swing back and forth, it achieves exactly that effect. The limited length of knives and saws makes this practically self-evident.

If a cutter is made to change direction very quickly, the effect is that of a longitudinally vibrating wire. The following course of events can be anticipated for a high vibration frequency: Thanks to its horizontal motional component, the wire not only penetrates more easily, it even induces local fluidization via vibrating pressure at the cutting point and therefore leaves behind a particularly smooth, integumental film on the sliced face.

3 Results

This project of the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ) was funded under the project number AiF 16074 N by the BMWi through the German Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF). and implemented by Brick Research Institute Essen Regd (IZF). The final report is 65 pages long and available for a handling fee from the Research Alliance of the Clay Brick and Tile Industry Regd in Berlin.