Direction-sensing mass flow sensor for temperatures up to 700° C

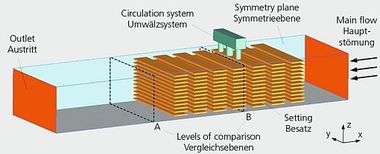

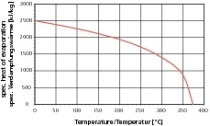

The special design of the sensor not only allows measurement of the mass flow and flow velocity but also the direction of the flow. A further advantage of the sensor is the completely enclosed nickel-chromium steel measuring tip enabling application even in polluted environments. Another feature is the high pressure resistance of the tip. For applications in extreme temperatures, the electronics have to be installed in room temperature areas. This is achieved with a 3 to 6-m-long nickel wire with fibre-glass insulation capable of withstanding temperatures up to 400° C.