testo 880 thermal imager: more advantages for industry thermography

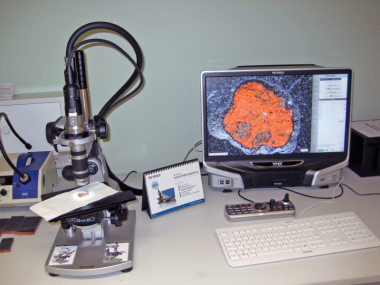

User friendliness and easy operation were the focus in the development of the new clearly structured professional software, which enables comprehensive analysis and evaluation of thermograms. More than one infrared image can be pro-cessed and analysed parallel, and documented with an associated real image in a thermography report. The new PC software can be used to compile multipage reports quickly and easily. For DIN EN 13187-compliant reports, the PC software includes special layout templates for detailed and simplified testing.

New too is the automatic hot/cold spot detection for instantly pinpointing hot and cold spots of the IR image display of the thermal imager. The user can mark, for example, the hottest spot

in mechanical components promptly on-site and at a glance.

A wide-angle lens and a telephoto lens enable adaptation to various sizes of and distances to the objects to be measured and guarantee the widest flexibility in different application conditions. The IR radiation is optimally utilized with the high-quality F1 germanium lens.

The testo 880 thermal imager with integrated digital camera and image-in-image function combines the real and IR images for fast

and reliable documentation. An exchangeable protection glass protects the valuable lens from damage. Thanks to the very high temperature resolution (less than 0.1° C), the testo 880 thermal imager can visualize friction, incorrect adjustment or tolerances of the components. In this way, production downtime can be avoided before problems arise.