1 Introduction

As visual beings, humans are able to see colours. No wonder then, that colours play an important role in all facets of our lives. Chromic diversity reflects the fact that we are able to express ourselves individually. Colour variants, effects and diversity of structure have found their way into the ceramic world, too, of course. For thousands of years now, people have been intentionally manipulating the surfaces of ceramic products. Thanks to modern colouring processes and colour effects, what once was a product of basically reddish or brownish colour has since amassed a practically infinite range of diversity and, hence, a new aesthetic dimension.

Producers concerned with ceramic surface refinement can provide a broad spectrum of pertinent options. In practice, distinction is made between engobe, glaze and pigment coating, in addition to such intermediate stages as glossy engobes.

2 Nomenclature

Roof tiles and bricks are, in general, ceramic natural products, the colours of which depend on the raw materials used to make them. The range extends from light to yellow-firing colours to different shades of red and on to brown.

However, ceramic coatings or pigments can be applied to alter the colour of heavy clay products. It is important that the coating be compatible with its substrate. Engobes and glazes have been serving well in such applications for many, many years.

Engobe

An engobe is a very fine-grained clay slurry or suspension intended for application to a shaped green product (tile, roof tile) by various means to serve as a coating and, hence, colouring layer. Sintering inseparably joins the engobe to the ceramic body. After firing, the surfaces appear flat to semi-glossy. If a glass-forming modifier is added, the finished product will be considerably more glossy, and the optical effect of the engobe will come closer to that of a glaze. In this case, the vitreous or glossy engobe forms a glassy coating.

Glaze

By contrast, glaze is a thin, vitreous coating on a ceramic body. Such siliceous coating can also be applied by various means, and firing also joins it inseparably to the substrate. To preclude subsequent glaze defects, glaze and body must be compatible in terms of thermal expansion.

Pigments

In most cases, the targeted colours are achieved with pigments. Any number of oxides and inorganic pigments are available. Brindling and structural effects are achieved by combining ceramic colours and pigments, hence also expanding the potential colour spectrum. Acting together with the nature of the body, this can yield interesting surface effects, particularly if the colouring layer is applied sparingly.

Additives

Diverse additives are needed to make engobes and glaze slips suitable for application and to give the slip or suspension the proper consistency. Additives serve to reduce the water content, adjust the viscosity or adhesion, etc. Some additives, like phosphate-based formulations, can mobilize metal ions from the body to produce special effects or intensify the colour.

3 Turning green products into coloured bricks

Engobes of diverse colours and shades have been around since the Middle Ages in Europe, since the Dark Ages in Islamic brick architecture, and even since Babylon’s heyday. Glazes also represent an age-old means of “sealing” porous ceramic bodies. Indeed, such glazes and glossy coatings were in use in Mesopotamia and Egypt a good thousand years before common era. Probably the most widely known form of engobe ceramic is terra sigillata, a Roman ceramic product with a relatively dense, red, glossy finish. There was also a black version called terra nigra.

Today‘s heavy clay industry has numerous engobing options in terms of mineral composition, optical characteristics, application techniques, firing processes, etc. Most producers of such coatings operate their own R&D laboratories, where individual solutions can be elaborated to fit both the ceramic body and the customer’s wishes. Unsurprisingly, a single producer can have thousands of recipes on the books. Consider the following, simplified production sequence for producing a colour-refined heavy clay ceramic product:

› �mine the raw materials

› �prepare the body

› �shape the product (e.g., by extrusion)

› �apply engobe or pigment to the wet body

› �dry the shaped products

› �apply engobe, glaze and/or pigments to the dry body

› �fire the product (firing temperatures: raw-material dependent; diverse firing processes and atmospheres: oxidizing or reducing)

› �subject the product to quality control

Most engobes and glazes are supplied in the form of powders or granules, but ready-to-use slips are also available on demand. Very rarely, pasty compositions are preferred. The slip, which is normally mixed application-ready at the factory, can be applied in a number of different ways. In the early days of ceramics, the only way to apply a glaze or engobe was to dip the body or douse it with slip. Nowadays, though, the coating can also be slung, sprayed or even rolled onto the body. These techniques are optimal in terms of equipment and costs. For example, spraying and rolling reduce the quantity of engobe required, as well as the amount of loss, and produce very uniform colour coatings that in turn help minimize the fired-product rejects rate. Such cost benefits are of major importance for producers of tiles and other heavy clay products. Firing completes the production process.

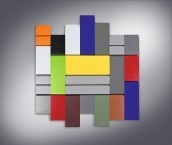

4 Product diversity of ceramic coatings

Today‘s producers of engobes and glazes offer an enormous range of surface-refining products for diverse colours and effects. Of primary interest are the customer’s own requirements, the technical conditions of production and, in that connection, the appropriate formulation. Intensive customer orientation together with a suitable sales network form the foundation for successful interaction between the producers of engobes/glazes/pigments and the manufacturers of heavy clay products. »Table 1 surveys the leading providers/producers of engobes and glazes and summarizes the essential pertinent information.

5 Outlook

Looking back over the past two decades, particularly with regard to glazes, one can see that the purely optical aspects are being increasingly joined by functional consideration as key issues. The use of nanomaterials to make ceramic surfaces easier to (keep) clean and the use of ceramic coatings with a biocidal effect have already become widely known, widely employed methods.

As far as engobes are concerned, new additives, functionalities, designs and structures are also sure to find their way into the field, and nanotechnology is also expected to gain importance. Nano-fine additives with photocatalytic effects could also be of advantage in engobes. Photocatalysis generates free hydroxyl radicals around the surface with an antibacterial effect. Moreover, nano-fine metal ions would make good candidates for limiting or even completely suppressing the growth of moss and lichens. One thing is for sure: the industry is blazing new paths and expanding its already huge range of recipes.

Literature/Literatur

[1] Zanger, H.: Dachziegel – Farbe und Oberfläche. Zi Ziegelindustrie International 5/2002, S.12-18

[2] Arbeitsgemeinschaft Ziegeldach: 5/2002; Fachinformation Dach-ziegeloberflächen

[3] Patwardhan, N.: New Handbook for Potters; 2005

[4] Krolkiewicz, H. J.: Dachziegel. Geschichte der Baustoffe. In: baustoff-technik. Gert Wohlfarth, Duisburg 2003

[5] Bender, W.: Lexikon der Ziegel. 2. Auflage. Bauverlag, Berlin 1995

[6] Fachinformation der Engobe- und Glasurhersteller