Bongioanni delivers extruder to Teknobrik, Algeria

Located around 20 km south-west of Algiers in Tessala El Merdja, Teknobrik is a company manufacturing hollow bricks. For a refurbishment project at the end of 2015, Teknobrik chose to place an order for a new extruder with Bongioanni Macchine, headquartered in Fossano, Italy.

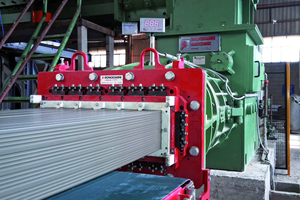

Already in February 2016, a Tecno 750 extruder and a 610D de-airing mixer were delivered, which could be commissioned in June 2016 to the full satisfaction of the customer.

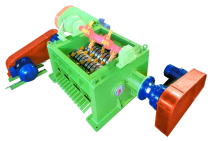

The Tecno line is equipped with state-of-the-art technology concepts for extrusion control, representing the most advanced technological level of Bongioanni extruders combined with low energy consumption.

Tecno 750 Mix 610D

The control board equipped with inverter controls the power uptake of the feeding reel motors, avoiding accidental overfilling of the extruder. Based on the data captured as reference parameters, it is possible to monitor the filling level in the de-airing chamber. Once minimum and maximum values have been assigned, the software records any changes and intervenes automatically by adjusting the frequency regulator that controls the main motor of the extruder. In this way the speed of auger rotation is modified according to the recorded data, with the additional advantage of maintaining the auger shaft at the optimum rotational speed.

This patented system allows:

»constant feeding of the clay body to the die, which means a more homogeneous density of the mixture, a more uniform thrust surface, and improved quality of the extruded products

»maximized efficiency of the extruder; energy consumption is reduced considerably when the auger runs consistently at optimum speed

»a longer lifetime of the extruder; minimized speed leads to less wear of the auger, linings, gear units, etc.

»lower maintenance costs for the machine and lower material costs

»exclusion of human error; operatives tend to set the auger speed higher than necessary “so as not to run any risk”, which, however, impairs efficiency

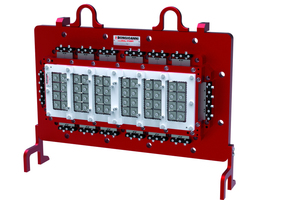

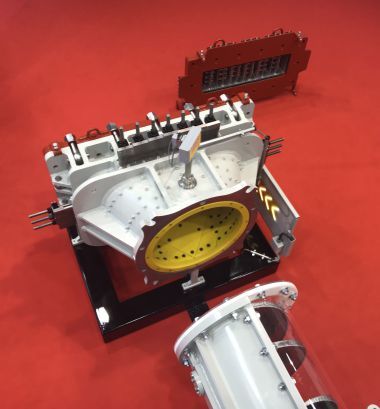

To complete the order, Bongioanni Stampi also supplied extrusion equipment consisting of pressure head with different taper, and the Gamma Plus die for B8 with six exits with frame and cores made of corrosion-proof BST02 carbide, a material that is well-known and rated highly on the Algerian market.

In the period from the year 2000 to date, Bongioanni has sold almost 230 extruders all over the world, of which at least two dozen have been installed in Algeria in the last few years.

Bongioanni Macchine S.p.A

www.bongioannimacchine.com