Drawing up energy balances for dryers and kilns as a basis for energy monitoring

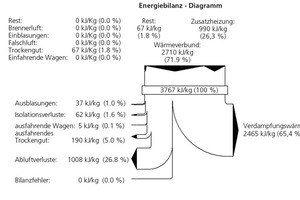

Basis for the energy audits is the drawing up of detailed energy balances and their understandable...