Filled clay blocks – an unstoppable trend

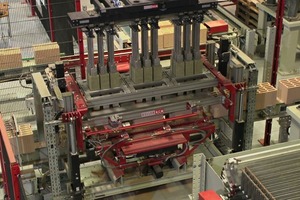

The crucial factor for the decision to award Keller HCW with the project was the unmatched flexibility the filling plant design offers. For example, the water-jet cutting technology employed together with the patented Keller HCW filling system can handle almost all laminar insulating materials. In addition to its high flexibility, the Keller HCW plant is perfectly suitable to fill unstable insulation boards with low material thickness into nearly all types of die geometries. This means for Wienerberger that they can react to all needs of a volatile market within the shortest time possible – a key advantage no other plant design can offer in this form.

New developments will no doubt change the still very young thermo block product group significantly in the years to come. The trend towards filled clay blocks, however, is unstoppable. Even if the end of this journey is not yet foreseeable, with a Keller HCW filling plant, customers are already well positioned to get there in the best way possible.