The new Optima technology

from Talleres Felipe Verdés, S.A.

from Talleres Felipe Verdés, S.A.

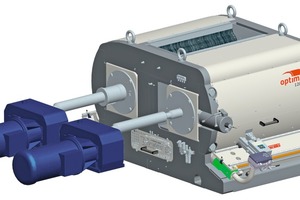

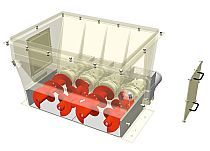

Talleres Felipe Verdés, S.A. has designed its new Optima range of roller mills to provide high capacity combined with high reliability and precision in operation. This is achieved thanks to a new much more robust and heavier bedplate design, and the incorporation of new control elements.

The new automatic roller gap system guarantees the required gap with a precision lower than 0.01 mm. The Optima roller mills offer a bigger range of dimensions and capacities using linings with widths from 600 to 1400 mm and with tangential speeds up to 21 m/s. They have the following features:

robust and stable bedplate, without deformations and vibration-free

high hardness linings

higher gap precision using an automatic control system for the roller spacing

bearings tolerance reduction

higher working precision between linings

better accessibility for maintenance tasks and spare parts replacement

low maintenance costs

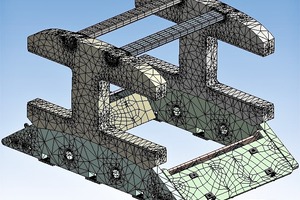

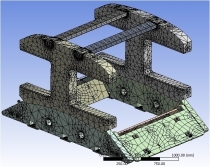

Designed based on FEA calculations

All mobile and structural components of the Optima roller mills have been designed using finite element analysis calculation programs in order to minimize deformations and to ensure that all new elements that make up the machines are precise and reliable (»1).

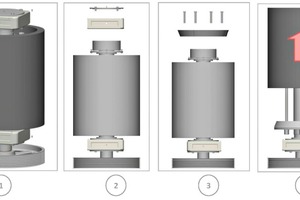

Easy roller replacement

Installing the rollers is very easy thanks to an easy-to-dismantle fixation system between roller and shaft, which guarantees perfect alignment. The new design allows the replacement of the roller lining without any need to take out the labyrinth and the bearings, reducing the time and the cost of the operation (»4).

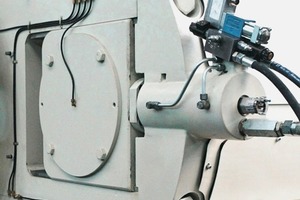

Gap control system

The Optima roller mills range offers the possibility to adjust the gap between rollers by means of a mechanical process (manually) or with a hydraulic process (automatically). The mechanical system allows the adjustment of the roller gap through the two bearings case movement, which are fixed by a screw system over mechanized cylindrical guides. The hydraulic system adjusts the movement automatically and simultaneously adjusts both bearing cases through a double piston system installed on the two bearing case bridges (»5 and »6).

With all these key design improvements, the new range of Optima roller mills is much more robust, heavier and vibration-free thanks to the new bedplate. On the other hand, it boasts improved precision thanks to the new automatic adjustment system. All this translates into higher quality.

Hall B2, Stand 405/506