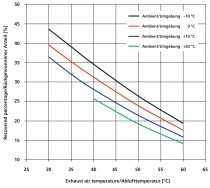

Using funding opportunities with the help of the new KfW energy efficiency scheme “Waste Heat Utilization”

The utilization of waste heat has been established in the clay brick and tile industry for many years, it is common for the waste heat from the kiln to be used to dry green products.

This involves repeated investment in new and/or replacement equipment. Here the KFW offers a funding scheme designed to support companies. Up to 40% of the usually substantial investment costs are possible. Particularly interesting is that the funding may be granted for all relevant technologies. The only binding criterion is the avoidance and/or utilization of waste heat. Process optimizations in the kiln-dryer combined heating system or measures for insulation of plants and pipelines are just as eligible for funding as, for example, the utilization of system air for preheating combustion air. A corresponding waste heat concept is compiled by a technical expert. The costs for this also qualify for funding. The energy efficiency scheme “Waste Heat Utilization” is available in two variants: as a straight grant scheme or as a credit option that generally includes a redemption subsidy of 30 %. There have already been several applications for the scheme supported by the Brick and Tile Research Institute IZF.

Dipl.-Ing. Silke Sabath, Institut für Ziegelforschung Essen e.V.