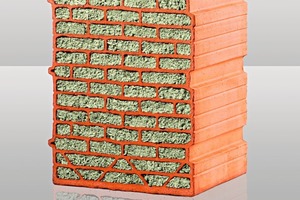

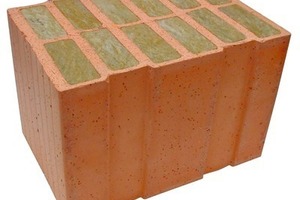

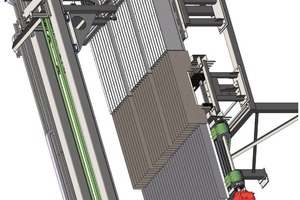

Filling plants for innovative heavy clay products with added value

A decade ago, at “Bau” 2001, Schlagmann introduced a perlite-filled brick called the Poroton T9. Bucking the trend toward increasingly filigreed perforation patterns, this compact clay masonry unit featured large, perlite-filled chambers. Then, at “Bau” 2007, a number of other brick and block producers exhibited similar stuffed products. And now, stuffed bricks and blocks have become well established on the German and, to some extent, the international markets. This market review explains what it takes to produce stuffed bricks and blocks.