More than ten years’ experience in building tunnel kilns for the clay brick and tile industry

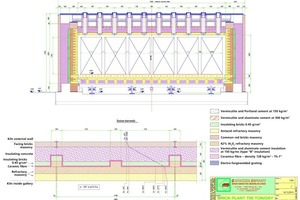

Since 1999 the Italian Capaccioli Group has been building various types of kiln for firing a wide range of products: from roofing tiles through facing tiles to thermal blocks and vertically and horizontally perforated bricks.

1 Introduction

2 Profile of Requirements

2.1 Low running costs thanks to low energy consumption and full...