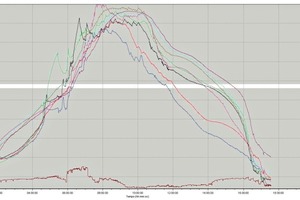

Practical experience with longitudinal and transversal recirculation systems in a tunnel kiln

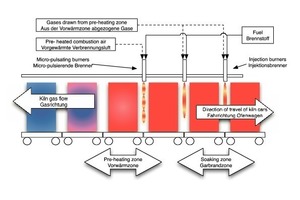

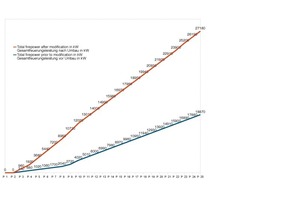

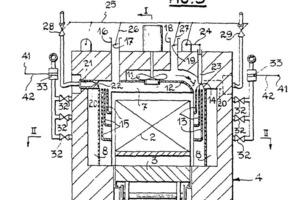

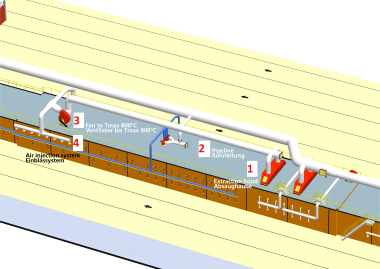

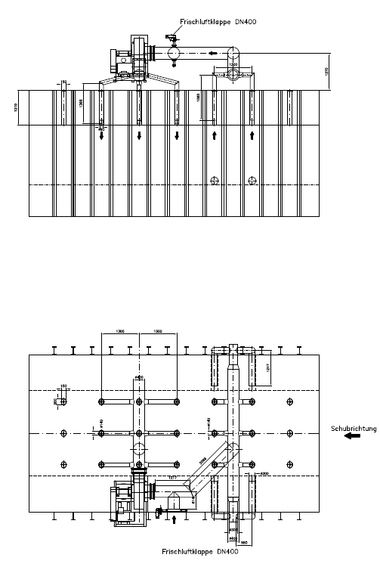

The objective of this project was to substantially reduce the specific energy consumption of a 168-m-long Lingl tunnel kiln, built in the 1970s, at a plant owned by Vela SpA – Borgonato, Corte Franca BS. The tunnel kiln is used for firing hollow and cored bricks. To achieve the desired results, it was not only necessary to make a number of modifications to the kiln and dryer, but also to adapt the feedstock used. This report focuses on the modifications to the kiln.

1 Introduction

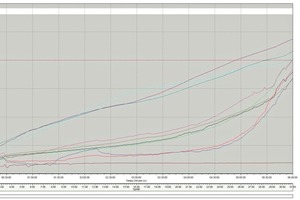

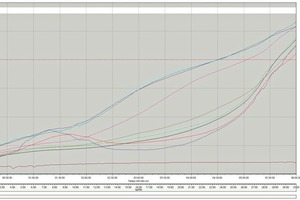

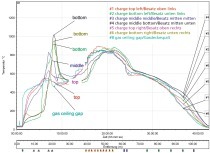

The tunnel kiln suffers from insufficient homogenization of temperatures in the kiln chamber. The operation of a tunnel kiln...