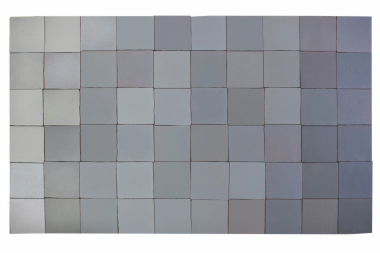

Challenges and trends in the surface finishing of

building ceramics

Cobalt has a long tradition in ceramic surface finishing – not only for blue shades.

Cobalt brings “depth” in black shades of black and can add sheen to glazes and engobes.

Where else is cobalt used? How much cobalt is there? Who has secured supplies of cobalt? Is there enough for all (industries)? How is it extracted? What possibilities exist to substitute cobalt so that at least black colours can be formulated with no or low cobalt content? What advantages are derived from this?

The talk will give answers to these questions and thought-provoking impulses.

Joachim Grothe, Vitreus GmbH