Clays from the Rhenish lignite mining – alternative raw materials for heavy clay ceramics

During opencast mining in the Rhenish lignite mining district, with the extraction of the coal, clays are also won from several-metres-thick and homogeneous mining horizons. The individual horizons differ in their chemical composition and mineralogy, resulting in a wide array of potentially usable raw materials. Studies on the suitability of clay raw materials from opencast lignite mines show that the clays won during opencast lignite mining are suitable for use in the ceramics industry.

1 Introduction

Lignite mining in the Rhenish mining district has a long history and has been going on in the region at the latest since industrialization in the 19th century.

In the three opencast mines Hambach, Garzweiler and Inden, around 90 mill. t lignite are mined each year, from which 70 to 75 TWh/a power is generated in the nearby power plants [1]. In addition, around 5 mill. t refined products are produced, which are used in decentralized cogeneration in numerous industrial operations as well as for environmental protection purposes. In geological terms, the lignite deposits form part...

![»2 SW-NE-cross-section through the layers of sediment in the Lower Rhine Embayment. a: Garzweile, b: Hambach, c: Inden ([2])](https://www.zi-online.info/imgs/1/3/5/1/8/1/1/tok_99b06586e1b95d8084695e4e8c521afc/w300_h200_x489_y356_Ginzel_Bild_2_SW-NO-Querschnitt_durch_die_Sedimentschichten_der_Niederrheinischen_Bucht-e61bd6cfc81ac51d.jpeg)

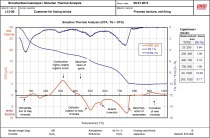

![»5 Differential thermal analysis (exothermic and endothermic reactions): 1. Dehydration2. Oxidation of the organics3: Dehydroxylation of clay minerals4. Oxidation of Fe-sulphidescf. [7]](https://www.zi-online.info/imgs/1/3/5/1/8/1/1/tok_c7a1ac561cbd4bb4253d301d1b6ae27b/w300_h200_x489_y316_Ginzel_Bild_5-67d35af6b57aef78.jpeg)

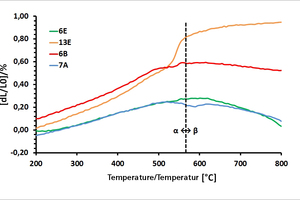

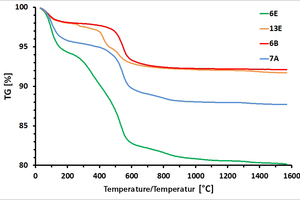

![»6 Results of the expansion-shrinkage analysis by means of dilatometry:1: Firing shrinkage 13E2: Sintering interval 6E3: Swelling interval 7ASintering point 6B [5]](https://www.zi-online.info/imgs/1/3/5/1/8/1/1/tok_3d9c8e70d5780280acdff1db741d7108/w300_h200_x421_y297_Abb._6-fd1545a47b2dfac2.jpeg)