Efficacy verification in energy management projects – Performance monitoring with mobile instrumentation

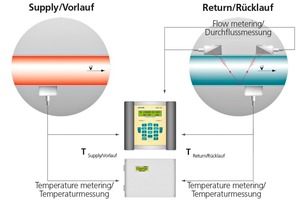

Source/Quelle: http://www.pce-instruments.com

Source/Quelle: http://www.pce-instruments.com

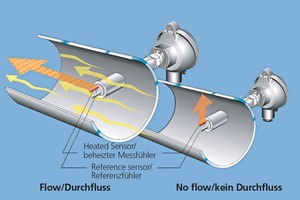

Source/Quelle: Flexim GmbH, www.flexim.com

Source/Quelle: Flexim GmbH, www.flexim.com

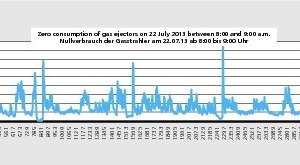

Source/Quelle: Fa. Binder GmbH, www.bindergroup.info

Source/Quelle: Fa. Binder GmbH, www.bindergroup.info

Source/Quelle: www.cs-instruments.com

Source/Quelle: www.cs-instruments.com

Source/Quelle: www.cs-instruments.com

Source/Quelle: www.cs-instruments.com

Source/Quelle: www.hds-messtechnik.de

Source/Quelle: www.hds-messtechnik.de

Anyone who practices energy management must be able to verify and document the efficacy of individual measures taken. In line with their current energy expenditures, the respective client enterprise is expected to maintain and provide online working data acquisition and appropriate controlling software. Efficacy verification can also be conducted in the form of performance monitoring by means of mobile instrumentation. This contribution elucidates a selection of mobile applications for efficacy verification.

1 Introduction

With regard to the reimbursement of energy/electricity taxes or of the EEG levy on renewable energy, energy management systems are currently a topic of concern, especially in the manufacturing industry. However, article 8 of the EU Energy Efficiency Directive also prescribes periodic energy audits for all other branches. The EU Energy Efficiency Directive entered into force in December 2012 and is slated for implementation into German national law before the end of 2014 (amendment of the Retail Energy Services Law). Within the scope of energy management implementation, all known...