Equipceramic starts up turnkey plant for Mehsas National Tuiles et Briques

Mehsas National Tuiles et Briques (MNTB) entrusted Equipceramic with the building of a new plant in Algeria, which is designed for a production capacity of 210 000 t/year hollow bricks.

MNTB was looking for a supplier with the experience to carry out this project on a turnkey basis. Equipceramic, S.A. was awarded the order for the overall project, from design of the installation, selection of the most suitable equipment, organization of the production flow method to training of staff.

On the basis of the results of laboratory analysis on the clays to be used, the decision was made to install a semi-dry grinding process. The clay is fed first to a wet pan mill, followed by a mixer and finally a roller crusher. This ensures a very fine grain size and consequently a high-quality finished product with a smooth structure.

The products are dried in a Celeris rapid dryer characterized by a very accurate regulation of the drying cycle, so as to obtain a high degree of efficiency. The main advantages of this type of dryer are a simple but sturdy design and an entirely automated operation system with a very low maintenance requirement.

The bricks are fired in a Gaudi tunnel kiln, which thanks to its sealing and insulation system as well as its combustion, ventilation and air recirculation circuits is one of the most high-performing energy-efficient kilns available.

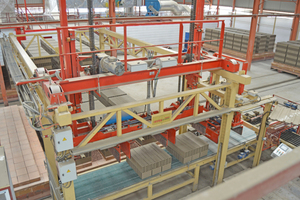

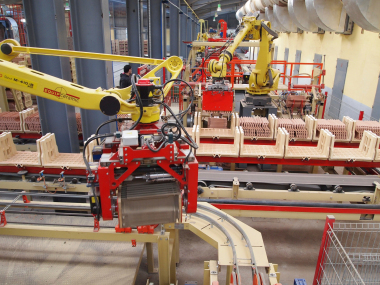

Kiln cars are unloaded on a layer-to-layer basis so it is easier to make dispatch packs according to the standard format in the country (1200 x 1200 mm). The pack-making station consists of two lines where packs are horizontally and vertically strapped before being loaded on trucks or stocked in the yard. The duplication of the line was necessary to reach the production rate required by the customer.

The first kiln car loaded with fired ware came out of the kiln at the beginning of December 2015. Since then, teams of technicians from both companies have been working together in the transfer of the required information and training so Mehsas’ technicians can manage operation of the plant completely independently. Equipceramic, S.A. will, of course, continue to provide Mehsas with technical assistance and advice whenever required in future.

Equipceramic, S.A.

www.equipceramic.com