Händle extruder E 25 successfully introduced to the Chinese market

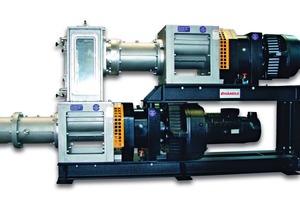

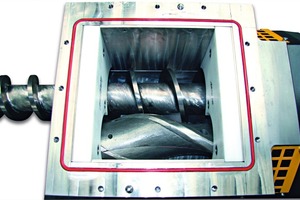

According to the order, the unit must prevent any and all contamination of the products, so Händle delivered and installed a rustproof version, i.e., one in which all parts in contact with the compound are noncorrosive. Like the well-known Futura II series, the E 25 is of modular design. Its body has plastic inserts to keep all material out of the shaft seals. A spiral feed roller is provided to counter the formation of dry lumps. The horizontal primary pug mill is equipped with paddles that help pull in slabs and filter cake. The extruder‘s barrel measures 200 mm in diameter and has a delivery rate of just under 2 m3/h, a maximum extrusion pressure of 50 bar and a power requirement of 22 kW.

In addition to the rustproof model, Händle also offers more inexpensive alternatives in the form of a standard version and a semi-rustproof version (meaning it has rustproof wear parts).

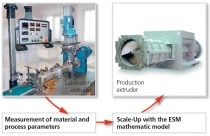

The extruder‘s service range covers structural, fine and engineering ceramics, including things like small building components, special profiles for tiles, honeycomb structures (roller-kiln rollers, slugs for table china, etc.).