Inauguration of the Gouda tunnel kiln

On 15 November 2013, Gouda Refractories BV in the Netherlands celebrated the inauguration of a new high-temperature tunnel kiln. In the presence of many top clients, project partners, employees and other guests, the Managing Director of Gouda, Marcus Schuchmann, and the CEO of the holding company Andus Group, Tom van Rijn, praised the performance of the new kiln as well as the professional cooperation with Lingl from project planning to completion.

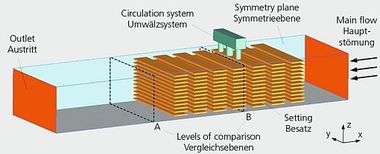

Gouda has implemented various modification measures to increase the plant’s capacity and has invested in a new high-temperature tunnel kiln. Compared to currently applied technologies, this innovative high-temperature tunnel kiln is equipped with Lingl roof technology, allowing for significantly quicker adaptation of the respective firing curves in case of frequent product changes. In comparison to suspended roofs, thermal losses are considerably reduced as this new roof does not require metal stays or ceramic suspension systems with high thermal conductivity. As to investment costs, there is also a considerable reduction owing to the fact that cooling air fans and piping are no longer required and the roof beam system is of more lightweight design.

The new Lingl robot setting installation equipped with the Lingl 3D setting pattern program has been commissioned too. All these modifications contributed to the increase of capacity by up to 60%.

The inauguration took place in a very festive setting and the catering as well as the live music put the guests in good humour. On the day following the inauguration, Gouda organized an “open day” on which the interested public was invited to visit the plant.