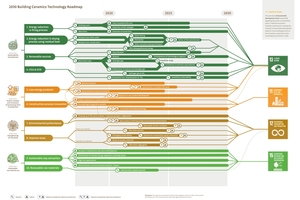

KNB’s Technology Roadmap 2030: A vital instrument for the Dutch ceramic industry

Author: Niels Bijleveld MSc

The Dutch Technology Roadmap 2030 aims to provide guidance and insight for both industry members and external stakeholders such as policy makers, on the feasability of various technologies to decarbonise the industry of building ceramics. It consists of various sustainability strategies that need to be researched, tested, demonstrated and, most likely, implemented. For example, defined and ongoing research will provide insights on whether hydrogen can actually be used in the ceramic production proces as a subsitute for natural gas. The same interest applies to using a mixtures of hydrogen, (bio)gas, or electric energy in production processes. Hence a lot of pioneering research will be necessary to provide answers to such uncertainties, and to discover succesfull alternatives for building a more sustainable ceramic industry.

Uncertaintiesof future energy infrastructure

But even if the industry is able to determine potential technologies for its decarbonisation, it also faces uncertainties like the (un)availability of future energy infrastructure. If a ‘hydrogen economy’ is compatible with ceramic production processes, will hydrogen be available in time and in the right quantities, price and quality levels on sites mostly based in rural areas in the Netherlands? Such externalities will have to be adressed by the gouvernement and grid operators. The Technology Roadmap could then also be used as a helpfull instrument to rightfully claim new specific energy infrastructure in the near future. A progress that is currently ongoing in the Netherlands.

In the meantime the industry is working on dematerialisation on various ceramic products in both prefab products and on-site construction techniques. Hence the function of bricks shifts from a load-bearing wall to exterior cladding with high easthetic properties for end-users, while leading to diminishing CO2 emissions per m2 of facade for ceramic production plants.

In addition to adressing uncertainties on product specifications and factory production processes by implementing new sustainable technologies, the essence of timely decarbonisation will be a topic of debate during the next years. Carbon prices, both on European as national level (!) are rapidly increasing, and will lead to very steep production costs in the nearby future. However, by testing the various alternatives of the Technology Roadmap and by providing transparancy on (intermediate) results, all stakeholders should be able to account for the decarbonisation efforts of the cermic industry.

Vital instrument of decarbonisation

Appraisal for the Dutch ceramic industry comes mostly from nature and conservation NGOs who understand the positive environmental and natural effects of clay mining and ecofriendly landscape restoration afterwards. This in turn leads to better flood control, water management, the creation of wildlife habitats, and to new carbon sinks. These benefits are often overlooked by policy makers, but will lead to new environmental and water management problems in the Netherlands once clay mining comes to a halt.

If needed, the Technology Roadmap can also be used to help explain and justify the need for additional assistance of the gouverment (or the EU) where necessary, in terms of resources, specific subsidies, excemptions, or other forms of ‘green industry’ policy. As the Technology Roadmap could adress many uncertainties of the Dutch ceramic industry, it will likely become a vital instrument to face the challanges of the energy transition and decarbonisation.