Large-volume feeders, fast firing decks and pulsed

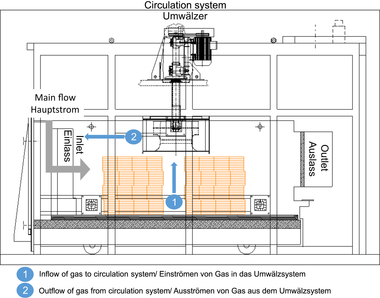

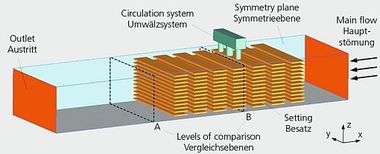

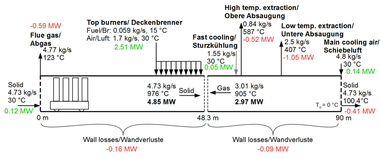

air circulation

air circulation

A. Hässler Anlagenbau is a plant engineering company founded over 50 years ago by Andreas and Gerda Hässler and is owned fully by the founding family.

Initially, engineering focussed on building complete tunnel kilns. At the company site in Erbach mainly kiln components are manufactured now. At the Taucha site, above all large-volume feeders with a filling volume up to 3000 m³ are built. At the trade fair stand, alongside proven products like the large-volume feeders and super lightweight decks for fast firing, innovative developments like pulsed air circulation will be presented.