Limitations of the use of circulation systems and their influence on the temperature and velocity profile in tunnel kilns

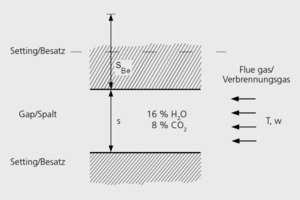

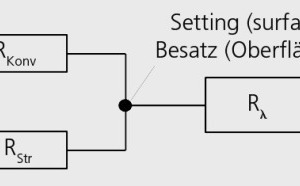

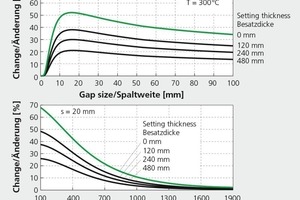

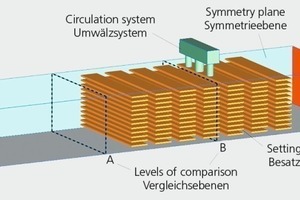

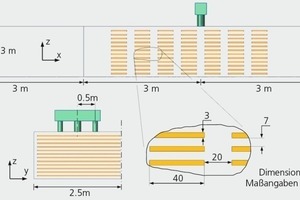

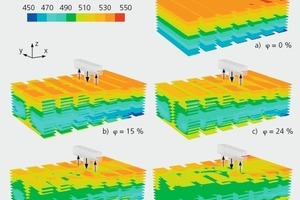

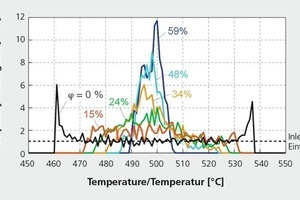

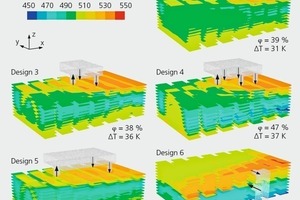

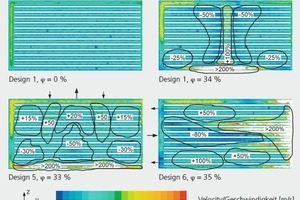

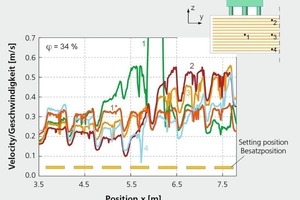

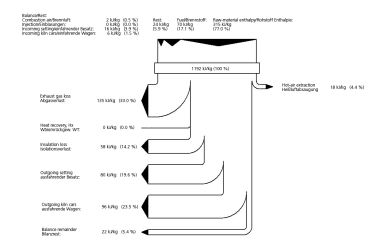

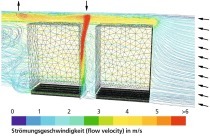

Heat transfer within the setting of a tunnel kiln car consists of a combination of convection, radiation and conduction. Based on the modelling of this heat transfer, the effective area of application of circulation systems is explained. It is shown what influence the gap width in the setting, the material thickness of the fired ware and the temperature range of the firing channel have on the increase in heat transfer with the application of circulation. With the help of computational fluid dynamics (CFD), different circulation systems are analysed. Their effect on the temperature and velocity profile of the kiln atmosphere on the flow of the kin gases through a setting stack is shown by way of example.

1 Introduction

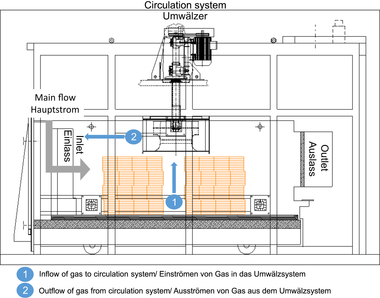

The use of circulation systems in tunnel kilns in the ceramics industry is state of the art. Suitable hot gas fans are commercially available up to 900° C. With regard to the type of circulation, however, each manufacturer pursues a different concept. Fundamental investigations of the effect of circulation on heat transfer and temperature homogenization in tunnel kilns are not known.

If the firing channel is regarded in simplified form as a counterflow heat exchanger, it can be mathematically proven that an improvement in the heat transfer between the kiln atmosphere and the ware...