Measures for reducing the effects of moisture on expansion and contraction processes and on loss of strength in industrially produced adobe bricks

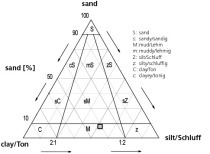

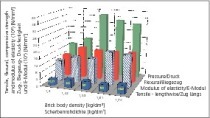

Various types of clay were tested for suitability in the production of extruded adobe bricks. Three of the twelve investigated varieties of clay were chosen for further testing in connection with the fabrication of adobe bricks satisfying modern quality criteria. Various mass fractions of traditional and modern additives were mixed into the loamy clays. The modified clays were extruded and subjected to alternating climatic conditions. Most additives were found to improve dry tensile strength and help prevent property drift. The findings of the research project are presented in this contribution.

1 Introduction

Earthen architecture has been in renaissance since the 1980s. The days in which people who build homes of clay were belittled as a tree-hugging minority are over.

Loam and clay have been serving as construction materials for many hundreds of years. No wonder, since loamy clay soil can be found in most parts of the world, often capping clay deposits. What could be more natural than to use it for building homes? Eventually, though, with the advance of industrialization and the use of such new mass materials as bricks – and, somewhat later, concrete – mudbrick and adobe gradually fell out of mode and were only used for home-building purposes in post-war periods and other times of scarce resources. Then, in the late 20th century, expanding ecological awareness rang in a revival for adobe construction. In Germany, the renaissance of earthen architecture breathed new life into old clay building techniques.

Like centuries ago, homes are now being made of tamped clay and adobe/mudbrick. In humid climates, the outer walls of earthen buildings always have some kind of weather protection to keep the clay from eroding. In Germany, buildings with load-bearing adobe masonry have thick outer walls, because their strength is moisture-dependent. At present, most adobe walls are merely partitions or even conventional walls with clay plaster on the inside, i.e., the clay is not load-bearing.

From an ecological standpoint, the material’s low-energy form of production is of interest. In the light of constantly increasing fuel prices and the resultant economic pressure on Europe’s brick and tile industry, the production of adobe bricks appears as a viable alternative or supplement to the…