Monitoring air-energy flow in the brick and tile industry

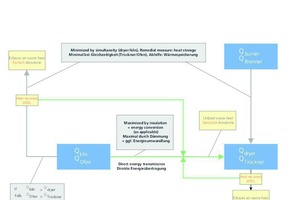

In practically all brick and tile-making plants, large volumes of air have to be handled, but the processes in question are only analysed and appraised at the time of commissioning, not in the further course of operation. This is where halstrup-walcher‘s “Luftmeister” monitoring solution comes in. Based on high-precision measurement of volume and mass flow in the air duct, the flow of air is not merely summated. With the aid of enthalpy and temperature sensors, the amount of thermal energy passing through the air duct is also determined. This steady provision of data on consumption and energy flow enables incorporation of the entire air-handling system and, in particular, the associated heat-recovery process into the plant‘s operational energy management system.

Over the past few years, most producing companies in the brick and tile industry have implemented an energy management system. Whether a company proceeds according to DIN EN 50001, as the leading energy management standard (mandatory for large companies as of 2016) or prefers to opt for environmental certification according to DIN EN 14001/EMAS, etc.), the key objective is to consume less media and energy and to document the resultant savings.

This reduction goal pursues three complementary motives:

reduce operating costs

make a positive, sustainable contribution to the environment

maintain or...