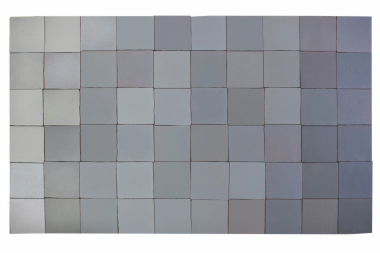

Natural fired colours of raw materials for bricks and tiles

The fired colours of heavy clay bodies are largely determined by the employed raw materials, the lighting conditions and the viewer‘s visual perception. The term fired product colour indicates that the colour in question is a body colour, or surface colour, the chromatic effect of which results from the reflection of ambient electromagnetic radiation. Body colour, by definition, is the visual perception of objects under the influence of specific changes in the diffusely reflected spectrum attributable either to the absorption of substance-specific wavelengths of optical radiation or to surface scattering.

The colour of ceramic bodies is mainly attributable to the presence of metal oxides and hydroxides. Reduction firing of clay brick products induces redox processes in which iron oxide plays a major role. Generally, the colour transmutes from that of a red, oxidation-fired body to that of a blackish-greyish-blue reduction-fired body.

Technically, such differences in colour can be identified by means of a colorimeter operating within CIE lab colour space coordinates. In many cases, the quantifiable differences in colour are indistinguishable to the human eye. Moreover, there is a clear correlation between differences in colour and the properties of the body deriving, for example, from the use of different firing temperatures. Thus, the colorimetric system serves both for determining the fired colour or differences in fired colour and for monitoring the consistency of product characteristics.

Dipl.-Ing. M. Ruppik, Institut für Ziegelforschung Essen e.V.