Optimizing the preheating zone in a tunnel kiln

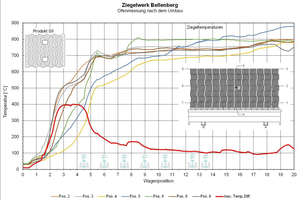

The rebuild project at the brickworks Ziegelwerk Bellenberg Wiest has a history that began more than ten years ago. The brickworks has been a Keratek client for many years, though “with brickworks, we are actually referring to the people involved,” says Christian Gäbelein, managing director at Keratek. In 2011, his predecessor, Karl-Heinz Brakemeier, and Bellenberg’s managing director at that time, Rüdiger Sattler, worked out the technically and economically optimum solution and implemented it together.

Already in the run-up to the project, when looking through the drawings, they established that the distances between the ceiling supports in the preheating zone of the tunnel kiln did not match up with the firing gaps on the kiln car. To position the first atmosphere circulators in the selected zone, modifications were necessary. This opportunity was taken to prepare the ceiling for two more installation points. The effort was worth it, as the Bellenberg tunnel kiln responded well to the optimization. The final measurements confirmed a positive influence on the product quality, energy consumption, and homogenization of the setting temperatures. However, a few years passed before the next step was taken.

Ceiling-integrated

solution

From spring 2019, the successors at the two companies started dealing with each other. Again it was to do with optimizing the preheating zone, which is particularly challenging for the production of clay blocks. The production mix at Ziegelwerk Bellenberg is now even wider and more diverse than before, and the setting weights on the kiln car vary widely. “Keratek brings experience from similarly complex projects, to further optimize the quality and energy consumption,” says Murray Rattana-Ngam, Bellenberg’s managing director. Following detailed discussions, he and Christian Gäbelein, together with operations manager Tobias Bem, are agreed that, with regard to technology, they want to stick with the ceiling-integrated solution. Five more atmosphere circulators are to be added to the two existing ones. As development has not stood still in the meantime, Keratek has upgraded the now seven fan units in line with the current electrical, mechanical and process engineering state of the art. All motors are frequency controlled and comply with the Premium – Efficiency class IE3.

The new control cabinets with plain text display are equipped with a network-compatible data logger, which saves the key operating data to a webserver. With the corresponding access data, the client has access from any internet-compatible terminal device to the temperatures and fluctuations of the individual machines. This information is, of course, also available directly at the machines, as is the maintenance interval for the cooling air filter and the relubrication intervals for the two shaft bearings. For the latter, permanent lubricators are being used for the first time at Bellenberg. With these lubricators, the cartridge is quickly and easily replaced during annual maintenance.

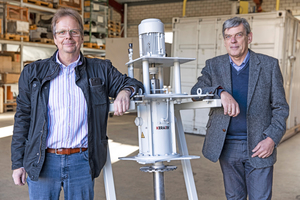

Intake spigots in the kiln ceiling

The special features of a Keratek Turboblock 800 circulating fan include that the two intake spigots are positioned in the kiln ceiling. There, they extract part of the kiln atmosphere and blow it back into the kiln chamber via an axial impeller directly in the firing gap. With the minimal losses on the pressure side, the atmosphere circulators work very efficiently. The 1.5 kW motor power is enough for a circulation rate of 3600 m³/h. When in operation with hot air, however, the power consumption of the atmosphere circulators falls below 1 kW. All pipelines that come into contact with flue gases consist of refractory material and are positioned on the intake side of the fan. For classical suspended ceilings, the atmosphere circulators are installed and insulated directly between the ceiling supports, without impairing cooling of the ceiling.

The Bellenberg atmosphere circulators are distributed in the preheating zone of the kiln, in the temperature range from 300 to 800 °C. They are installed in a staggered arrangement and a burner pipe is planned next to each fan to enable the installation of high-velocity top burners. When heavier products have to be fired, this allows faster and controlled preheating to the set temperature. The intensive turbulence in the kiln atmosphere leads to much more homogeneous setting temperatures and moderates the early, steep temperature rise in the outer and top layers typical for settings of clay blocks containing poreformers. Burnout is delayed to the prefiring zone, which enables better utilization of the energy incorporated in the clay block bodies. Accordingly, this energy can be utilized to heat the actual clay blocks more than just the flue gases.

High-temperature circulating fans with much greater energy efficiency

When heat is transferred by means of convection, the flow velocity plays a big part. For a long time, the view was that circulation only makes sense in the temperature range up to around 500 °C, that is where heat transfer is based primarily on convection, because above that temperature heat radiation has a greater effect. That is basically right, but only applies when flow velocities are below 5 m/s. If the outlet velocity is increased to around 20 m/s, it is possible to extend convective heat transfer into the maturing temperature zone for firing clay blocks and to verifiably lower the specific energy requirement there, too.

For high ware settings, the reach of the circulating fan is generally an issue. The project partners opted to equip all seven fans on the pressure side with a nozzle specially developed for these applications behind the guide wheel. With this nozzle arrangement, the jet of hot air is more focussed, and the flow velocity is increased right down to the deck of the tunnel kiln car.

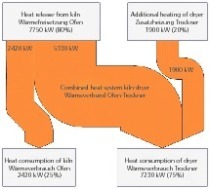

In many tunnel kilns, in the higher temperature range (600 – 800 °C), high-velocity burners are installed for temperature homogenization. Energy input is not usually necessary for the process and, in isolated cases, it can even be detrimental. With the use of high-temperature circulating fans, a much more energy-efficient solution is achieved.

Reduction of gas

consumption

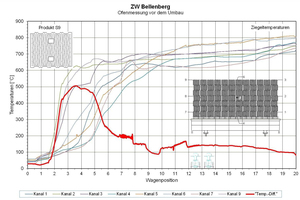

Kiln measurements after conversion show the expected convergence of the setting temperatures and a flatter temperature rise from the preheating into the pre-firing zone. The poreformers burn out in a more controlled, steadier process. In combination with two modernized burner rows and refurbishment of the kiln ceiling insulation, after the conversion, the client was able to register a reduction of the gas consumption in the lower double-figure percentage range.

The optimization of existing kilns is an important element to achieved the CO2 goals set by the brick and tile industry itself in its Roadmap 2050. In contrast to future technologies like hydrogen and electric heating, atmosphere circulating systems are available in the short term and can be integrated without the need for any massive intervention in the plant engineering. They are therefore not only a bridging technology, but suitable or even absolutely essential for alternative heating systems in the long term.

Support in the scope of the BAFA programme

Keratek’s rebuild project at Ziegelwerk was supported in the scope of the BAFA programme Energy Efficiency in Industry – Module 4: “Energy-Based Optimization of Plants and Processes”. After corresponding application and approval, this attractive support programme grants investment subsidies of 40 to 50 % of the investment for small- and medium-sized enterprises (SMEs) and even 30 to 40 % financial subsidies for larger companies. With regard to applying for and securing subsidies, the project was stewarded by Silke Sabath at the Brick and Tile Research Institute in Essen.

Förderung durch das BAFA / Beratung durch das IZF

Das Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA) fördert mit dem Investitionsprogramm Bundesförderung für Energieeffizienz in der Wirtschaft Maßnahmen zur energetischen Optimierung von industriellen und gewerblichen Anlagen und Prozessen zur Steigerung der Energieeffizienz sowie zur Nutzung von Wärme aus erneuerbaren Energien und von Abwärme für gewerbliche Prozesse in Unternehmen. Die Förderung ist technologieoffen.

Das Institut für Ziegelforschung Essen (IZF) unterstützt Ziegelhersteller bei der Beantragung der Fördergelder und begleitet bei der Projektierung. Ansprechpartnerin im IZF: Dipl.-Ing. Silke Sabath (www.izf.de).

Die Keratek GmbH ist ein Ingenieurbüro für keramische Technik, das sich auf die Entwicklung und die Umsetzung von innovativen Technologien und Konzepten für die Baustoffindustrie spezialisiert hat. Karl-Heinz Brakemeier gründete das Unternehmen im Jahr 1986 und hat die Firma Ende 2013 im Rahmen der Altersnachfolgeregelung an den jetzigen Geschäftsführer Christian Gäbelein übergeben. Zum Angebotsspektrum gehören neben der Beratung bei Fragen der thermischen Verfahrenstechnik auch der Bau von Heißgasumwälzern für Tunnelöfen und das Projektmanagement bei komplexen Umbau- und Investitionsprojekten. Mit Dr. Wolf-Hasso Reschke ist seit Juni 2020 ein ausgewiesener Experte für Anlagenoptimierung und thermische Verfahrenstechnik bei Keratek beschäftigt.