PT Pro EZ belt centring stations are effective even with damaged belts

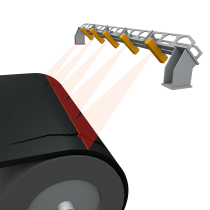

Misalignment of the conveyor belt is a frequent cause of material loss in conveyor systems. Belt centring stations can detect this and correct it. The latest such system in Flexco’s product range is the PT Pro EZ. One special feature is that the belt guide roller is polyurethane-coated as standard. This increases the service life and gives it better traction when moist.

The new belt centring station is suitable for light to medium-duty applications and for reversible belts with belt widths up to 1 200 mm. The station is very quick and easy to fit thanks to the simple design of brackets and components. With the help of the proven PT Pro Belt Trainer, conveyor system operators can also use this system on belts with worn or damaged edges.

The new belt centring station corrects belt misalignment on one or both sides. No sensor rollers are required as the tapered rollers initiate movement of the belt guiding system. The unit responds immediately to misalignment and corrects it. It also ensures that the belt does not touch the structure, thus preventing damage and reducing maintenance costs.

A special feature of this solution is the pivot and tilt movement. Pivoting affects the direction while tilting increases the tension on the incorrectly guided side. These two forces therefore move the belt quickly back to the centre. The belt centring system is suitable for belt speeds of up to five metres per second. It can be used in both damp and dry environments.

Flexco Europe GmbH

www.flexco.com