Practical application and experience with micro gas turbines

By reason of its high overall efficiency, combined heat and power generation (CHP) is both ecologically beneficial and, in many cases, economically quite attractive. The brick and tile industry, with its continuous need for heat and electricity, has recognized this potential. Motor-based solutions, however, are still relatively rare in this branch of industry due to the nature of the attendant heat supply.

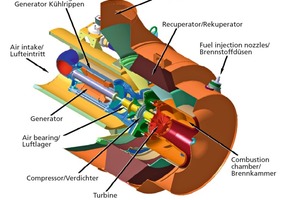

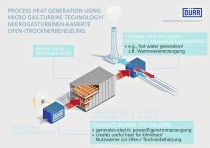

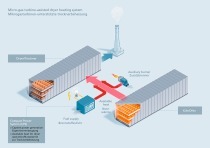

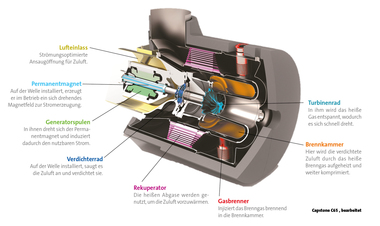

Thanks to their technological features, in particular for the direct utilization of waste gas, micro gas turbines serving as CHP units are opening up new ranges of application in the brick and tile industry. The term micro gas turbine defines small, high-speed gas turbines with electric power ratings up to 250 kW. Such units consist of a single-shaft turbine, a single-stage radial-flow compressor and a radial-flow power turbine. The permanent magnet in the generator is also firmly attached to the shaft.

This presentation explains the subject technology, presents examples of potential applications in the brick and tile industry, and illuminates its economic efficiency in the current context. The relevant impacts on the approval status of brick and tile-making plants according to the German Federal Emission Control Act (BImSchG) and with respect to other administrative requirements (e.g., accreditation by the German Federal Office of Economics and Export Control – BAFA, interconnected system operation) also are described.

Dipl.-Ing. Franz Obermeyer, Ing.-Büro für Energieeffizienz und Umweltschutz