Programme to promote Decarbonising in Industry

Germany’s Climate Change Act specifies the stepwise reduction of greenhouse gas emissions by at least 55 percent overall on their 1990 level by the target year 2030. In the long term, Germany’s federal government is pursuing the objective of achieving greenhouse gas neutrality by the year 2045. Being responsible for around 20 percent of the total emissions, industry is the second largest emitter of greenhouse gases after the energy sector (36-percent share) in Germany. At the same time, industry is of pivotal importance for Germany as a centre for business. Industry therefore plays a key role in achieving greenhouse gas neutrality.

Author: Sebastian Varga

Over the past 30 years, industry has already made considerable efforts with regard to climate action, however, greenhouse gases emitted by industry have been falling at a slower rate since the start of this century. Besides increased efforts to improve energy efficiency, now so-called springboard innovations are needed, based on the introduction of new production processes to make process chains and operations climate neutral in future.

Causes of industrial greenhouse gas emissions

In addition to energy-related greenhouse gas emissions, industry also accounts for process-related greenhouse gas emissions, which make up around 25 percent of the total industry emissions. In the industrial sector, three kinds of emissions are generated:

1. Direct energy-related greenhouse gas emissions result from the use of (fossil) fuels to generate energy (e.g. process heat, steam, mechanical work).

2. Indirect energy-related greenhouse gas emissions result from the generation of the electricity used (e.g. with a coal-fired or natural-gas-fired power plant).

3. Process-related greenhouse gas emissions are emissions caused primarily by technology- or process-related use of certain input materials in the production process (e.g. coke in steel production or limestone in the production of cement and lime).

Around three billion euros in funding

With the funding programme Decarbonising in Industry, Germany’s Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) is supporting energy-intensive industries in Germany in the transformation process to greenhouse gas neutrality.

Energy-intensive industries form the backbone of the German economy. Decarbonizing, however, poses a formidable challenge for them on account of their high energy- and process-related CO2 emissions. As the second largest emitter of greenhouse gases in Germany, the industry sector is a pivotal factor for achieving Germany’s climate action goal by 2030 and the goal of greenhouse gas neutrality by 2045 as set out in German legislation.

The funding programme for Decarbonising in Industry is aimed at making German industrial sites more climate friendly and sustainable, safeguarding jobs and creating new ones. The German Ministry for the Environment is making a total of three billion euros available by 2024 to subsidize investments and climate action contracts for decarbonizing energy-intensive industries.

What is eligible for funding?

With this programme, the BMU is co-funding projects in energy-intensive industries to largely and permanently reduce process-related greenhouse gases that cannot be avoided at all or only with great difficulty with the state of the art.

Who is eligible for funding?

In the funding programme Decarbonising in Industry, those companies working in trade and industry in a sector which is covered by the EU emissions trading scheme and which generates process-related emissions are eligible to submit an application. These include companies from the steel, chemicals, non-ferrous metals, lime and cement sectors as well as other energy-intensive industries. Funding recipients must operate business premises or a branch in Germany. Projects for which a funding application is submitted must be realized in Germany. Consortia of companies are also eligible to apply for funding. Higher education institutions, universities and research institutes may also be involved as project partners.

How is funding awarded?

Funding is awarded as a grant/investment grant as part of a co-financing concept. The Competence Centre on Climate Change Mitigation in Energy-Intensive Industries (KEI), a division of the company Zukunft – Umwelt – Gesellschaft (ZUG) gGmbH, has been commissioned by the BMU to manage the funding programme. With its headquarters in Cottbus, the KEI is making an active contribution to structural development in Germany’s Lusatian region. A 20-strong team is currently working on realization of the BMU funding programme and related aspects.

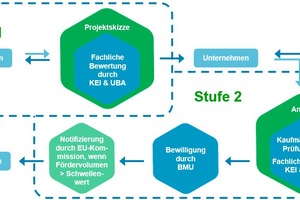

What is the procedure for funding application?

Applications for funding in the scope of the programme must complete a two-stage procedure. In the first stage, an outline of project is submitted, which is then assessed by experts at the KEI and German Environment Agency (UBA). Following positive assessment, the second stage involves the creation and submission of a formal application for funding.

Das BMU-Förderprogramm Dekarbonisierung in der Industrie ist

gestartet. Welche Aufgaben übernimmt das KEI?

Das KEI ist als Projektträger direkter Ansprechpartner für förderinteressierte Unternehmen. Die Aufgaben umfassen die Förderberatung, Antragsprüfung, die laufende Begleitung der meist mehrjährigen Projekte sowie die Evaluierung der Ergebnisse. Dies geschieht in enger Zusammenarbeit mit dem Umweltbundesamt.

Wen adressiert das Förderprogramm?

Im Förderprogramm „Dekarbonisierung in der Industrie“ sind Unternehmen mit prozessbedingten Treibhausgasemissionen förderberechtigt. Das sind schwerpunktmäßig Unternehmen aus den Branchen Stahl, Chemie, Eisen- und Nichteisenmetalle sowie aus der Kalk-, Zement- und Glasherstellung sowie weitere Branchen.

Der Entwicklungsstand einer Technologie muss mindestens einem bestimmten technologischen Reifegrad, dem sogenannten Technology Readiness Level (TRL) 4 entsprechen. Das heißt, sie ist im Labor geprüft und soll nun im Rahmen von Demonstrations- oder Pilotanlagen im industrieorientierten Umfeld getestet werden, um die Technologiereife bis zur Marktreife zu steigern. Das bedeutet, von der Forschung und Entwicklung bis zur Praxisanwendung wird eine Förderung aus einer Hand angeboten.

Wie lang ist die Laufzeit des Förderprogramms?

Aus europarechtlichen Gründen ist die Förderrichtlinie zunächst bis Ende 2023 befristet. Projekte mit längerer Laufzeit können in diesem Zeitraum aber bewilligt werden. Sobald die Europäische Kommission die über 2023 hinausgehende Genehmigungsgrundlage geschaffen hat – deren Überarbeitung läuft derzeit – kann die Laufzeit der Förderrichtlinie verlängert werden. Das Bundesumweltministerium plant eine Mindestlaufzeit bis 2030.

Welche Resonanz auf das Förderprogramm erwarten Sie aus der

Industrie?

Das Interesse aus der Industrie ist definitiv hoch und Ideen für Dekarbonisierungsprojekte sind in allen Branchen vorhanden. Wir haben bereits eine Reihe von Beratungsgesprächen mit Industrieunternehmen zu deren Projektideen geführt. Ich gehe davon aus, dass eine Reihe von diesen und weiteren Projektideen im Laufe des Jahres zu konkreten Förderanträgen werden.

Welche Tipps können Sie Interessierten für einen erfolgreichen

Fördermittelantrag geben?

Ich empfehle den Unternehmen als erstes das persönliche Gespräch mit uns zu suchen und uns dabei die konkrete Projektidee vorzustellen, bevor mit der Ausarbeitung einer Projektskizze begonnen wird. In diesem Gespräch können wir vorab klären, ob das Projekt grundsätzlich in das Förderprogramm passt bzw. wie es ggf. weiterzuentwickeln ist. Und selbstverständlich stehen wir im gesamten weiteren Antragsprozess beratend zur Seite.