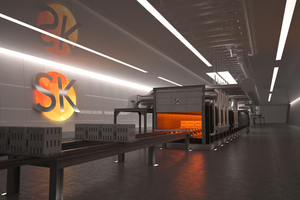

Skate – a new low-energy tunnel kiln

At ceramitec 2015, Direxa Engineering, LLC, USA, and its French R&D partner Ceritherm presented an innovative concept for a low-energy tunnel kiln with the name Skate Kiln. With this new concept, products are no longer loaded onto cars for firing and nor are they supported and transported by means of mechanisms that move through kiln like in roller hearth kilns for instance. We spoke to Christophe Aubertot, Managing Director at Direxa engineering, LLC, about the advantages of the new firing technology.

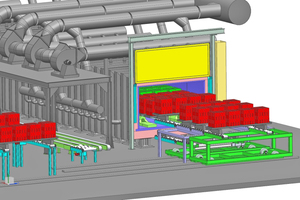

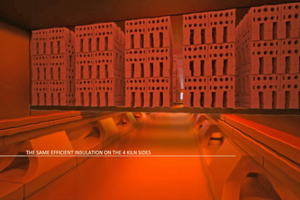

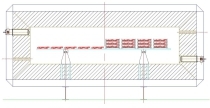

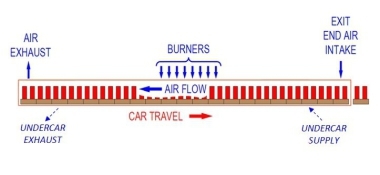

The basic principle of this kiln is that the “firing chamber” has four fixed sides: two walls, a roof and a bottom (hearth). The products, their supports and the moving media are all housed completely in the “firing chamber” so that all three are always at the same temperature. In addition, the weight of the product supports and moving media is drastically reduced compared to traditional technology with kiln cars: it typically represents 8 to 10 % of the product weight as opposed to 50 to 100 % of the product weight...