Test methods for heavy clay ceramic raw materials: ceram-technological behaviour (secondary properties) – part 2

Prior to designing any dryer and kiln layout, Lingl always conducts comprehensive raw material tests. This is the basis for high-quality products made by Lingl’s customers. This two-part article presents those laboratory tests at least necessary from the point of view of the plant supplier as well as supplementary tests. Part 1 of the article (Zi 4/2013) deals with material analyses of the raw materials (primary properties). Part 2 presents tests on the ceram-technological behaviour, i.e. the drying and firing behaviour (secondary properties) as well as possible tests on pilot-plant scale.

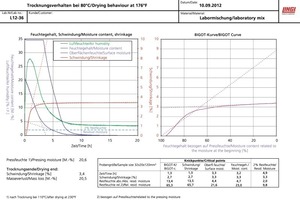

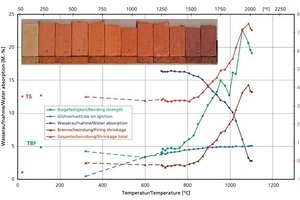

3 Ceram-technological behaviour (secondary properties)

3.1 Preparation and shaping