Always on the move - the long passage through the kiln!

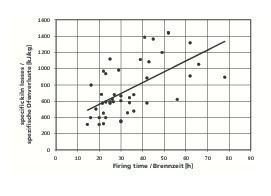

In the ceramics industry, especially in brick production, kiln passage times are often very long. The bricks are often in the kiln for several days until they have reached the desired firing. Problems and unexpected kiln stopps and delays can occur from time to time on this long passage.

A customer from the brick production industry approached us with a request to see whether it would be possible to record not only the temperature but also the push rates of the kiln cars. This should make it possible to localise any delays or stops that occur during the kiln passage and compare them with the measured temperatures. PhoenixTM has retrofitted the tried-and-tested PTM12 data logger and equipped it with a motion sensor that reports every kiln car movement to the software so that the user can see at a glance at which point in the kiln and at which tunnel kiln car problems have occurred.

This logger is currently in the final test phase. Very successful field trials have already been carried out with the prototype. It will be ready for series production in spring this year, so PhoenixTM will be presenting the data logger at this year‘s Ceramitec in Munich from 9 - 12 April 2024. Visit us at our newly designed stand in hall A4 / stand no. 104 - we look forward to seeing you there!