Evaluation of Resource Efficiency on the Use of Natural Stone Powder in Silicate Ceramic Bodies – Part 2

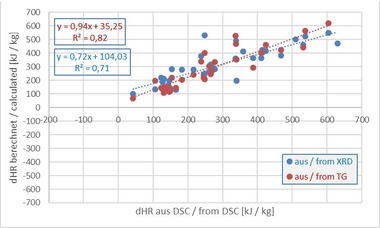

The issue of energy saving is of major importance for the ceramics industry. In addition, analysis of the respective resource consumption is shifting increasingly into the focus of interest [1, 2]. Sensible utilization of industrial waste in ceramic bodies in energy, economic and ecological terms requires knowledge of the energy and raw material consumption as well as the CO2 emissions for the manufacture of ceramic products. From this, potential savings for the use of secondary raw materials as well as for an efficient use of resources can be derived.

5 Evaluation of resource efficiency based

on the example of the use of diabase flour

for clinker production

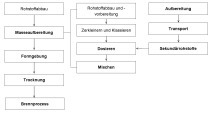

5.1 Changed process chains and data collection

5.1.1 Body components

The diabase flour S2, is produced as undersize during rock extraction for aggregate production (for concrete/asphalt, base courses in road construction, chippings, sand and ballast). Characteristic values are also detailed in »Table 3. For the calculations performed as part of this...