Halabja new clay brick plant goes into operation

Production

To ensure rapid and optimum ventilation for long bricks, Sabo has implemented a newly designed semi-continuous dryer. The two-sided ventilation of the bricks is followed with a combination of moving and rotating fans. Short drying times from 14 up to 20 hours are now realized even for standard format bricks. At the entrance of the dryer, special triple moving fans have been installed while at the exit rotating fans are fitted. Bidirectional and symmetrically distributed streams of air dry the bricks without cracks. An additional moisture recirculation is very helpful for water evaporation procedures at temperatures exceeding 100° C.

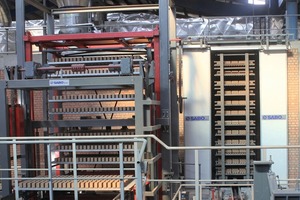

After drying, the products are loaded to the setting machine in the same way as they are loaded to the dryer. This consists of two programming benches, incorporating all mechanisms for creating a variety of setting layers. Defined patterns are set by means of the robot technology for each separate product in order to effect uniform firing of the packs.

Two groups of side and top gas burners, with separate ventilating systems, under a Scada supervision system, make for the trouble-free firing. Defined menu and process flows for each separate product offer outstanding drying and firing control even in the case of difficult-to-dry products. At the exit of the kiln, another robotized machine takes care of the dehacking and packaging of the product.

Two 700-kg robots unload all kiln cars layer by layer and set the bricks on two programming benches. A certain programming takes place on the second and third layer of the final pack to create the necessary space for forklift handling and thus to eliminate the necessity of wooden pallets. This type of packing system is commonly installed by Sabo in countries in which the costs for wooden pallets are very high.

Before the packs are removed and loaded onto the trucks, they are dipped in water with the help of a dipping device.

After unloading, the empty kiln cars undergo cleaning and maintenance before they are sent back to the setting machine.

The project has been successfully delivered and all production targets have been met thanks to the close collaboration between the customer and the Sabo team, their effective communication and tight project management.