Successful production start at “La Escandella” in Spain

At the end of 2014, the Spanish company “La Escandella” placed an order with Lingl for substantial modification work in its roofing tile factory near Alicante, Spain.

Headquartered in Alicante, La Escandella has become one of the leading European manufacturers of high-grade clay roofing tiles in less than ten years. Founded in 1967, the company is internationally active in more than 60 countries and is equipped with the latest plant technology with fully automated production processes. For instance, two of the production facilities for roofing tiles with the highest production capacity are owned by the Spanish group of companies.

Lingl was awarded the contract to convert the roofing tile production in the existing plant from firing in U-setters to firing in H-setters in order to meet the strong demand from the reinvigorated market for roofing tiles with even more sophisticated products. The challenging task for Lingl was to meet the deadlines of the extremely tight schedule as well as the customer’s high quality demands.

Fast, fully automated format change

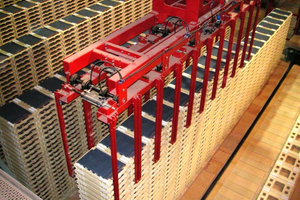

The production facility was equipped with a completely new setting and unloading installation as well as an installation for transport pack formation. The new setters were provided by La Escandella. In order to optimize the entire process, the handling of H-setters and roofing tiles was realized by reusing the existing equipment and by adding equipment with the latest handling and gripping technology combined with the most recent automatic control technology. This was one of the reasons why it was possible to realize customer’s requirements in their entirety with regard to a fully automated and quick format change. The customer’s high demands for the quality of the final product were top priority during the entire project and could be met to full satisfaction.

The existing Lingl packaging installation was integrated in the new S7 control system and included in the present installation.

The plant is currently designed for an annual capacity of 17.5 mill. roofing tiles. With increasing demand, however, the concept already provides the possibility to double the output quickly and economically with the installation of equipment at specific points in the operation.

Thanks to the close cooperation between the two companies, from design to commissioning, only 15 weeks passed between plant shutdown and production start. 100 % performance with first-grade products could be reached in less than eight weeks.

Only thanks to the cooperation between Lingl and La Escandella, and especially with the customer’s company and plant management, based on partnership and professionalism during processing of the entire project could the quick and successful completion of the order be realized with regard to technology, costs and deadlines.