Heat economy in brickyards,

with special allowance for asynchronies in dryer and kiln operation

1 Context

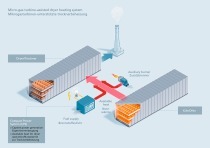

This type of integrated heat economy appears as a seemingly and practically ideal concept. The large amounts of cooling heat from the tunnel kiln are productively employed for drying purposes within the same plant. The only drawback is that tunnel kilns and dryers cannot be operated in total synchrony, because the time history of heat demand for drying does not fully coincide with that of cooling heat liberation. Consequently, the interconnected form of heat economy employed at brick-making plants has until now been regarded as worthy of improvement on that point, but otherwise unquestioningly accepted.

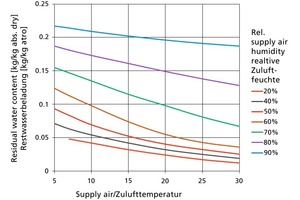

In recent years, however, having gained a better understanding of the parameters that govern the energy consumption of dryers, not only IZF but also brick people in the field of research and diverse plant and equipment contractors with heavy clay industry involvement have begun to alter their basic attitude toward the practice. People are beginning to realize that low-energy dryers satisfying contemporary criteria can be operated in reliance on the moisture absorbency of ambient air, but nonetheless equipped with modern control, ventilation and automation technology. Compared with most dryers now in use, these modified “atmospheric dryers“ use markedly less energy.

In addition, latest developments have produced tunnel kilns in which most of the cooling air is utilized within the kiln itself. This requires incorporation of high-temperature circulating systems that can ensure well-balanced cross-sectional temperatures profiles and heat transmission. In such a kiln, temperature equalization can be achieved without the heating-zone burners that have always been considered indispensable. The kiln can be operated with a fundamentally constant air-to-brick ratio along its entire length without having to expel large amounts of cooling air. The residual amount of cooling air still to be expelled is equal to the mass flow of combustion gases entering the kiln by way of the burners, and therefore contains only 20% to 40% as much integrated energy as “normal“.

2 Results

The combination of low-energy dryers and tunnel kilns that use their own cooling heat and therefore give off only a relatively minor amount of interconnected energy has thus created a whole new situation with regard to heat economy in the brick and tile industry.

The thermoeconomically essential instruments, including the calculation programmes for the simulation of drying and firing processes appended to the final report, are intended to put heavy clay producers, their technical personnel and the field‘s plant and equipment contractors in a position to discover for themselves the advantages of the exhaustively explained new concepts and to simulate the function of (at first only) theoretically retrofitted kilns and dryers.

The relevant mathematical models and computations of modified kilns and low-energy dryers illustrate their particular thermal economic advantages. Due to the high initial cost involved, the explications include ways and means of incrementally implementing the overall concept in order to more quickly benefit from lower energy consumption.

The objective of the research project was achieved.

Against a handling fee, the 103-page final report, together with a series of programmes for thermal-engineering calculations and simulations, is available from the Research Alliance of the Brick and Tile Industry Regd (FGZ) in Berlin.