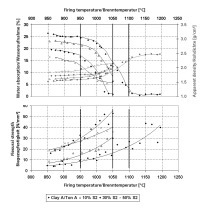

Evaluation of Resource Efficiency on the Use of Natural Stone Powder in Silicate Ceramics Bodies – Part 1

The issue of energy saving is of major importance for the ceramics industry. In addition, analysis of the respective resource consumption is shifting increasingly into the focus of interest [1,2]. Sensible utilization of industrial waste in ceramic bodies in energy, economic and ecological terms requires knowledge of the energy and raw material consumption as well as the CO2 emissions for the manufacture of ceramic products. From this, potential savings for the use of secondary raw materials as well as for an efficient use of resources can be derived.

![»1 Process chain for the manufacture of ceramic products with the use of secondary (waste-derived) raw materials (on the basis of [12, 13])](https://www.zi-online.info/imgs/tok_509f255b1dc6e8aa40ce7ef0e5f99f9b/w300_h200_x400_y214_101471290_2c801be9b6.jpg)