Perlite-stuffed masonry bricks –

progressing from innovation to sales mix

Exactly 10 years ago, at the “Bau” 2001 trade fair, Schlagmann exhibited the world’s first masonry brick with a heat-insulating core of natural perlite. In the meantime, the company has expanded its programme to include perlite-stuffed, rectified bricks for the full duty range of any and all exterior wall materials. At this year’s “Bau” in Munich, we talked to Schlagmann’s managing director Johannes Edmüller about these products’ engineering and future prospects.

Zi: Your presentation of the perlite-stuffed Poroton-T9 at Bau 2001 was a sensation. Contrary to the general trend toward increasingly filigreed core patterns, you presented a solid, thick-webbed brick with perlite-filled chambers (“perlite” being a natural mineral volcanic rock). How did you arrive at this innovative idea?

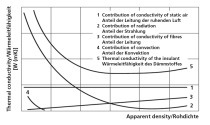

J. E.: By the late 1990s, it had already become clear to us that ever-thinner brick geometries and increasingly filigreed core patterns would not suffice to meet progressively strict thermal insulation requirements for exterior wall products. We therefore proceeded to develop a stuffed solid brick with which to optimally satisfy such other physicostructural requirements as acoustic insulation, structural stability and material strength. Extensive experimentation with more than 50 different thermal insulating materials produced results that led to our decision in favour of perlite, a natural rock that has been serving well in the building industry for decades now. However, we refrained from installing our own perlite preparation plant, because we wanted to remain receptive for new developments. Now, 10 years later, we are still relying very successfully on perlite, and in our view, there is no better filler material for clay masonry units.

Zi: Nowadays, nearly all major engineering contractors are offering brick filling plants. You, though, after breaking new ground a decade ago, are the only producer we know of to still be using perlite. Would you please give us a brief rundown on what it takes to fill bricks with perlite?

J. E.: Well, the filler bricks made of special clay blends are dried and fired at the brickyard and then transferred to the filling plant. Perlite of various description is received, stored in silos and filled into the bricks through templates on a vibratory feeder, with a little extra pile of perlite left standing over each chamber. Then, a ram descends briefly to press the material into each chamber, after which the brick is turned over and the compression process repeated on the other side. After that, the bricks are dried for about two hours at 140° C in an even-flow dryer to harden the bonding agent in the perlite. Finally, the bricks are packaged for delivery. The original filling plant was supplied and installed by Keller, and since we are still thoroughly satisfied with it, we ordered all our new filling plants from Keller HCW, too.

Zi: At first glance, the product looks extensively unchanged, but the Poroton T7, with its thermal conductivity of 0.07 W/mK, is definitely more insulative than the T9 (0.09 W/mK). What is the difference?

J. E.: Yes, a lot has happened since then. For one thing, the bricks’ core geometries have been significantly optimized. For another, the perlite has also been decidedly improved over time. For example, the T7 contains a much finer size of grain than that used in the T9. Thanks to intensive research efforts, the ceramic aspect has also made major progress in recent years in terms of much-improved thermal conductivity. With the Poroton-T7 now exhibiting thermal conductivity on the order of 0.07 W/mK, we have arrived at a dimension we would not even have dreamed of a few years ago.

Zi: Is 0.07 W/mK about “as good as things can get” with regard to the thermal conductivity of masonry bricks, or is there still some developmental potential left?

J. E.: Oh, the innovations are just getting started, I am sure! For decades now, our company’s motto has been “When you stop improving, you stop being good”. Perhaps there will be no more quantum leaps as far as thermal insulation is concerned, because we really are near the end of that scale already, but there is still plenty of potential with regard to acoustic insulation, structural stability and product processing. The “Dryfix System” we introduced at “Bau” stands as a typical example. This new type of placement dispenses with thin-bed mortar and accelerates the work by up to 50%. Developed by our partner Wienerberger, this system is already being applied with much success in Austria, Italy and Poland, where nearly half of all rectified bricks are now being set that way.

We also intend to concern ourselves more energetically with healthy housing environments. With that in mind, we have already extended our cooperation with the highly acclaimed Sentinel House Institute.

As you see, then, we do not intend to stop at giving good thermal insulation. We want to optimize the entire product “brick”.

Zi: In 2007, the Unipor Brick Group debuted their “Coriso” clay masonry unit at “Bau”. After that, various heavy clay producers came out with similar products. Why do you think it took so long for competitor products to appear on the market?

J. E.: I, too, was surprised that it took so long for producers to pick up on the idea. My impression was that they were waiting to see how well our system would fare on the market. Of course, such innovation processes are very time-consuming and, above all, expensive, so new solutions do not just pop up overnight, particularly in our kind of industry with a population of small and medium-sized enterprises. In addition, the road to certification is long and expensive, especially for such high-tech products with thermal conductivities on the order of 0.07 W/mK. We started working on the idea in 1997, and it took until 2001 for the product to become presentable. At “Bau” 2011, though, I was very happy to note that all relevant producers of exterior wall building materials are now offering products with integrated fillings.

Zi: Most other stuffed bricks are filled with mineral wool or rock wool, while Schlagmann continues to rely on perlite. Is that right?

J. E.: Yes, the main reason for this is that it took us 11 years to win a patent dispute about our perlite-filled bricks. Now, a decade after we developed the system, it is quite clear to us that perlite is the best heat-insulant for use in combination with heavy clay products. Basically, however, we want to leave the final decision for a particular product to our customers – meaning we must be able to offer a selection. Consequently, about a year ago, we decided to also start filling some products with mineral wool. Just now at one of our facilities, we are in the midst of installing a large new plant with an investment volume of 2 million euros. When it is finished, we will have three production lines for perlite-stuffed units and be able to produce exterior wall blocks with mineral-wool fillings at two different plants.

Stuffed bricks presently account for 70% of all our exterior wall products and for a good 30% of our overall output!

Zi: You say you have perlite-stuffed rectified bricks for all exterior wall material applications. Just which products are available in which formats?

J. E.: To begin with, we have perlite-filled Poroton/Porotherm blocks for energy efficient detached and duplex homes. That series carries a “T” for thermal – in reference to the heat retention. With U-values ranging from 0.07 W/mK to 0.09 W/mK, these products are available for nearly all conventional wall thicknesses between 30.0 cm and 49.0 cm.

For buildings with elevated acoustic insulation requirements, such as apartment houses and other residential complexes, we have the Poroton-S range, with “S” standing for sound. Best-achievable sound insulation is very important in buildings where lots of people live or work under one roof. The Poroton-S10 is available for wall thicknesses of 30.0 cm, 36.5 cm and 42.5 cm. A 36.5-cm wall of Poroton-S10 cuts noise by a fantastic 52.1 dB with a thermal admittance of only 0.25 W/m²K. All S-range clay masonry units satisfy both the German acoustic insulation standard DIN 4109 and the requirements of the German Building Energy Conservation Ordinance 2009 – naturally without need of supplementary, artificial thermal insulation for the exterior walls.

Altogether, Schlagmann has a current range of 200 heavy clay products. Our sophisticated logistics help us handle this enormous variety of products from our five different locations. For smaller brickyards producing at only a single location, such a broad array of products would be much more difficult to accommodate. Perhaps we brick people should all try to pare down our assortments a little in order to keep pace with competitors in terms of commercial viability.

I expect unrectified masonry bricks to gradually disappear from the market because of their time-consuming placement and inferior thermal insulation properties.

Zi: At “Bau” 2009, Schlagmann also presented an innovative ceramic heat-insulating façade called the Poroton-WDF. Designed for use in thermally rehabilitating old buildings, the WDF presents an effective, ecological alternative to conventional thermal insulation composite systems. How successful has it been on the market?

J. E.: The Poroton-WDF really hit the bull’s eye. We have noticed that today’s exterior insulation systems are being increasingly scrutinized for ecological and sustainability reasons, and the purely mineral-based WDF appeared on the market at exactly the right time. Eighteen centimetres thick, it serves as thermal insulation on exterior walls. Since we are convinced that future applications will also include its special use as interior insulation for upgrading the energy efficiency of exterior walls, we have added a new 12 cm-thick WDF to the product range. One very nice example of these products’ application was the energy efficient renovation of a heritage-protected wooden façade on the upper storey of a house. The building was insulated on the inside – and rendered energy-efficient – with WDF.

The successful results were underlined by the bestowal of Bavaria’s 2010 energy award by the Bavarian Ministry of Economics. That encouraged us to forge ahead and play our part as brick people on the huge rehabilitation and renovation market.

Zi: Which new products do you have on show here at “Bau” 2011?

J. E.: Well, for one thing, we are presenting our expanded range of stuffed bricks, including the aforementioned Poroton-T7 and the Poroton-S10 for multi-family homes. Likewise, the Dryfix placement system will also be in the spotlight, and the “warmest brick in the world”, the new Poroton heat-insulating façade with a thermal conductivity of 0.055 W/mK, will also be sparking the visitors’ interest. We will be presenting our new product range for the fireplace, too, such as a clay block chimney with a fine-particle separator.

Zi: Bricks used to be called “decathletes” because of their many unbeatable properties, but their thermal insulation capabilities are what have been getting the most attention in recent years. What are clay bricks going to look like in the future? Where would you say the trend is heading?

J. E.: I think clay bricks have an enormous future potential, and I am very happy to see that this year’s “Bau” adopted “sustainability” as its motto. For clay masonry, that means that lopsided concentration on thermal insulation can be put to rest and that all those other important physicostructural aspects can get back into the picture.

Vapour permeability, healthy home environment and fire protection, along with ecology and longevity, are the criteria for which clay bricks will prove even more superior in the future. Just for example, a major engineering firm recently conducted a study comparing three different systems: concrete plus a thermal insulation composite system, sandlime bricks plus a thermal insulation composite system, and Poroton-S10 with an integral perlite filling. Particularly with regard to sustainability, the monolithic system scored the best by far. In terms of 50-year life cycle costs, including first costs and renovation expenditures, the monolithically insulated wall has very obvious advantages. With regard to ecobalance and renewability, not to mention disposability, clay masonry is way ahead of other, more conventional systems. So, I am looking forward very eagerly to what the future has in store for clay masonry in Germany.

Zi: You are now managing Schlagmann Poroton as a medium-sized, family-owned business in its third generation. How do you see that in connection with your joint venture partner Wienerberger AG?

J. E.: Correct: With our 280 employees at five locations in Bavaria, we consider ourselves an innovative mid-range company. The fact that we have Wienerberger AG, the world’s leading producer of clay units, on board as our partner is of inestimable value. For exactly two decades now, we have been plying the market successfully with this 50:50 constellation, and we have gone through thick and thin together over the years. Most particularly the hard markets of the past few years have shown how robust our partnership is, even in difficult times. Our collaboration has been very successful, and we intend to keep it that way for decades to come – in Schlagmann’s fourth generation.

Zi: How intensively is your company dealing with things like “renewable energy” and “prevention of CO2 emissions”?

J. E.: Those are two key topics at Schlagmann. We are constantly at work on lowering the primary energy requirements for our products and have targeted the ambitious goal of producing the first-ever CO2-neutral clay brick by the year 2020. Our first few steps in that direction have been quite successful. All our electricity now comes from renewable sources, especially hydropower. We have the confirmation of TÜV Süd on that. We also generate our own “clean” electricity on many of our facilities’ roofs, and we have three solar farms in operation with a total output of 4 MW, which, of course, greatly benefits the ecobalance of both our products and the entire company. We intend to keep doing all we can to further reduce our energy consumption – perhaps including the use of biogas.

Zi: As president of Ziegelzentrum Süd in Munich and of Deutsche Poroton in Berlin, what do you think the building volume will be this year and next?

J. E.: With a market share of approximately 43%, clay bricks are still the most popular wall-building material for residential projects in Germany. In that respect, current developments in the housing sector are of very decisive importance for us. We were very happy to note, for example, that the available building-permit data from 2010 indicate an anticipated gain of up to 15% in construction volume for 2011.

That is what I call wind in our sails. On the other hand, I expect the next few years to see a shortage of masons. Due to a permanent decline in construction volume over the past 15 years or so, our partners in the field have reduced their manpower by more than 50%. As a result, there are already too few qualified tradespeople out there for working with our products. We intend to counter that trend with suitable systems like prefabricated wall elements and increasingly faster, more economical placements system like Dryfix.

As a medium-range enterprise, we also want to get more young people interested in the building trades. With that in mind, we established the Schlagmann-Edmüller Foundation and gave it an initial endowment of 1 million euros as a contribution to the promotion of young talents and trainees in the building sector. This will include social projects as well as training initiatives and honouring the achievements of outstanding trainees in the field.

Zi: Mr Edmüller, thank you very much for this informative conversation. We wish you and your company much continued success.