For high-quality mixing – Händle‘s re-engineered double-shaft mixers

Its most important functions therefore include homogenization of nonuniform raw materials, blending of different raw materials, mixing in of additives, additional raw materials, water and disintegration of superficially dry materials. Consequently, a double-shaft mixer can be used at various points of the preparation process specific to the task at hand before, during or after comminution, as well as before or after clay storage. Before raw materials are put in storage, for example, a double-shaft mixer can be used to closely adjust the material‘s moisture. On retrieval, it can likewise serve to disintegrate superficially dry material.

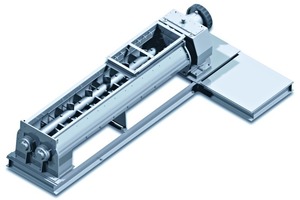

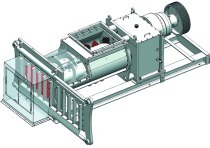

The two mixing knife-studded shafts are driven by an electric motor acting on a belt drive, planetary gear and spur transfer gear. The mixing blades on the contra-rotating mixer shafts are arranged to intermesh and achieve very intensive, thorough kneading via radial and axial interaction of the motional axes. This effect can be intensified by installing as many as 12 fixed knives in the mixing trough. The mixing knives have an adjustable angle of inclination, hence enabling – in case of need – adjustment of the mixing quality and throughput rate by simultaneously altering the speed of the mixing shafts.

Like all Händle-built machines, these double-shaft mixers feature excellent longevity and ease of maintenance. Their one-piece mixing trough has a hard-wearing inner lining, their shafts have protective sleeves in the mixing zone, and their knives have removable (= replaceable), hard-wearing faces. Double-shaft mixers come in four different sizes for different throughput rates. They are mounted on a base frame for quick and easy installation, and a side catwalk is available on option. Various other options, such as moisture control, make it possible for us to build customerized double-shaft mixers for any individual set of requirements.