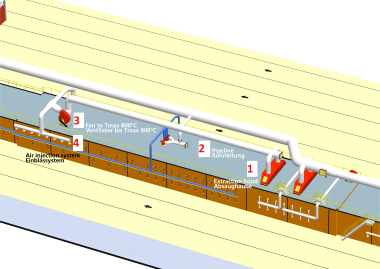

Oxide-ceramic continuous fibres and ceramic fibre reinforced composites – innovative materials for the firing process

Energy conservation, efficiency and lightweight construction are future-oriented topics with a close connection to the advent of highly refractory continuous ceramic fibres and filaments. CeraFib GmbH designs and produces such fibres, filaments and other materials suitable for service under fluctuating temperature conditions (up to 1350° C) and in aggressive environments under mechanical stress. These materials are therefore ideally suited for the particular challenges of kiln construction. CeraFib‘s advanced fibres earned the company a nomination for the 2011 Saxon Innovation Award.

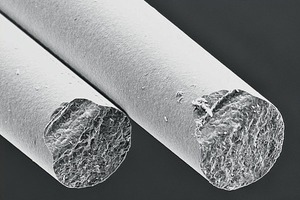

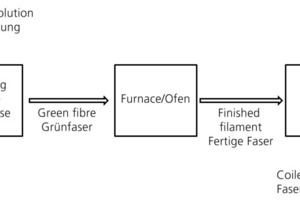

1 Oxide-ceramic continuous filaments

The market for refractory insulating material is presently dominated by mineral fibres and short ceramic fibres based on aluminium oxide. For high-tech applications however, i.e., among the ceramic composites, there is urgent need for high-performance ceramic fibres with better high-temperature ageing behaviour in oxidizing atmospheres than that displayed by the few alumina and Al2O3/SiO2 filaments that are presently available – and...

![»1 Multifilament in the heat of a gas flame [1]](https://www.zi-online.info/imgs/tok_f8019a5d27198bdf0c54c3e0cc384ab6/w300_h200_x400_y600_101474936_f5c11f2e57.jpg)

![»6 Continuous fibre reinforced composite under thermal strain [1]](https://www.zi-online.info/imgs/tok_871f1ebfa7ffe25eec802c1e3de933e0/w300_h200_x400_y600_101474910_9de7d57730.jpg)