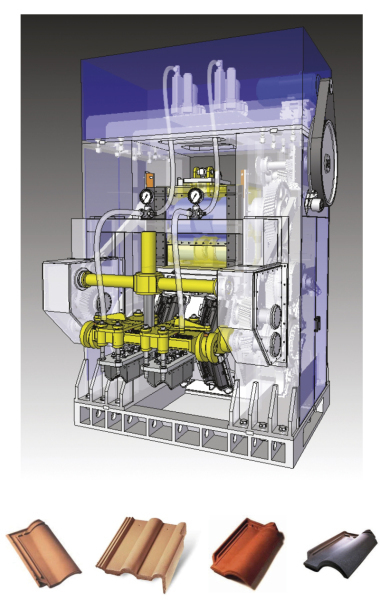

Bedeschi equips P.T. M. Class Industry with new three-mould roofing tile press

For P.T. M. Class Industry, an Indonesian roofing tile manufacturer, Bedeschi is supplying a new pressing line and widening its broad range. The new production line will be equipped with a vertical mixer (GDG 1500), an extruder (BED 500 SLS), a cutting and a feeding line, a new three-mould press complete with moulds and a special setting machine (manufactured in-house in Bedeschi’s workshop) to take up 18 tiles at once and load them on a dryer pallet.

Bedeschi S.p.A.

www.bedeschi.com