Continuous reduction firing in a tunnel kiln

In the firing of heavy clay ceramics, the reductive process of transforming Fe2O3 into Fe3O4 can be used to generate numerous different colours, i.e., to obtain a very variegated interplay of colours. It can be used to generate the kind of colours that are very well-received in modern architecture. This way, brick and tile producers can make their products more attractive not only in terms of shape, but also in colour and hue without need of engobes. In addition to sporadic reduction (flashing), it is only logical to run a permanent reduction atmosphere in a tunnel kiln. That, however, requires that attention be paid to a few process-engineering and structural particularities.

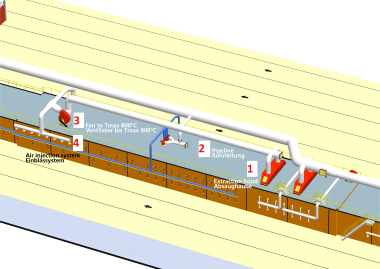

Taking a production kiln as an example, this report illustrates the requisite measure for achieving sustained reduction.

Rainer Hüsing, Keller HCW GmbH