High-porosity mineral foam –

an alternative insulating material

an alternative insulating material

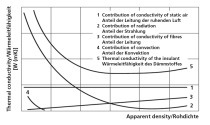

To improve the thermal insulating properties of wall-building materials, thermally insulating materials are introduced into the existing chambers. The currently preferred filling materials for wall-building materials are mineral wool, perlite, mineral granulate, expanded polystyrene particle foam granulate (EPS) and, in isolated cases, resol hard foam. The above-mentioned materials are produced in time- and resource-intensive processes (e.g. high-temperature processes) or sometimes based on petroleum products.

The presented processing and material solution approach concerns the development of a physically produced mineral foam that does not derive its porosity in a chemical gas formation or thermal production process. Instead, air is dispersed in a liquid suspension and the surfaces between liquid and gas phase stabilized with boundary-surface-active substances. The specific combination of hydraulically hardening binders leads to the solidification of the foam structure in less than 10 min. This enables a high filling rate and continuous further processing of the wall-building materials filled with foam.

Because of their comparable thermal insulation properties, physically produced mineral foams are seen as a complement to the existing inorganic thermal insulation materials.

Dr.-Ing. Barbara Leydolph, Dipl.-Ing. Attila Höchst

IAB – Institut für Angewandte Bauforschung Weimar gGmbH