Short-term heat storage in the heavy clay industry

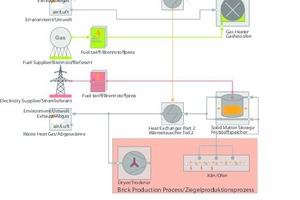

As part of a European research project, new solution approaches centring on compact, easy-to-handle short-term heat storage are to be demonstrated. Sensitive and latent heat storage materials are considered within the scope of the project. Special attention is focussed on the development of integrated systems, i.e. storage units that serve as an energy management tool and are combinable with a microturbine/cogeneration system. The measurements are to cover a large range in the industry. Varying process states in different brick plants and storage possibilities are presented.

1 Introduction

The manufacture of clay bricks and roofing tiles involves a very complex production process. Slight deviations in the composition of the clay body, the shaping parameters or the drying and firing conditions affect the entire process [1].

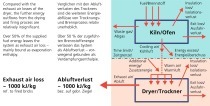

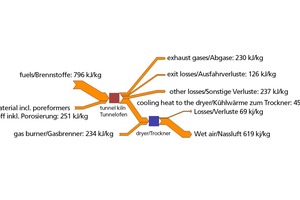

In terms of thermal engineering, the dryer and tunnel kiln are the most essential installations in brick and tile plants. A key feature of these is that, aside from losses caused by leakages, cooling of structural components and insufficient thermal insulation of the structure, the energy requirement covered by the fuel supply is defined by a...

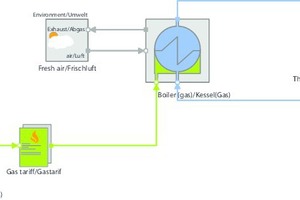

![»2 Basic set-up of the CellFlux [3]](https://www.zi-online.info/imgs/1/3/2/6/9/4/4/tok_cd8c702665855d2cd782f21047fa72a3/w300_h200_x240_y162_Bild_2-4caa2740e188bbdf.jpeg)

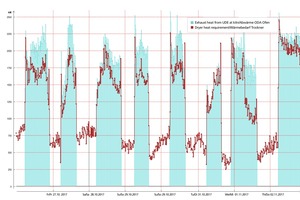

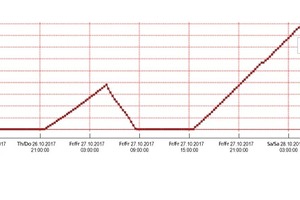

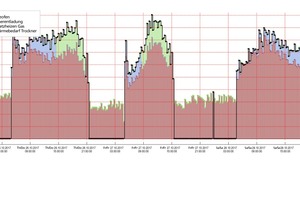

![»3 Time curves of cooling heat and dryer energy requirement [4]](https://www.zi-online.info/imgs/1/3/2/6/9/4/4/tok_4c680d7a6e7dc423f23bf32ec56e26c7/w300_h200_x600_y270_Bild_3-3a414a756e2d9542.jpeg)