Why use radically new kiln concepts – and how?

For quite a few years now, the US American company Direxa Engineering, LLC and its business partner in research and development, the French company Ceritherm, have been working on radically new ideas for continuous kilns for the ceramics industry. This article documents the status of their progress.

1 Introduction

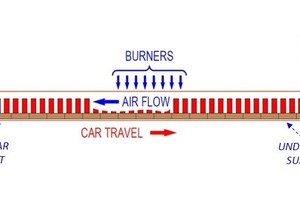

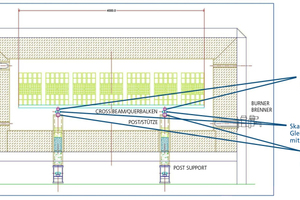

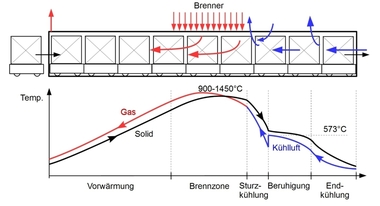

In the ceramics industry, a tunnel kiln can be simply defined as a continuous furnace where products to be fired and the heating/cooling air travel in opposite directions, as schematized in »1.

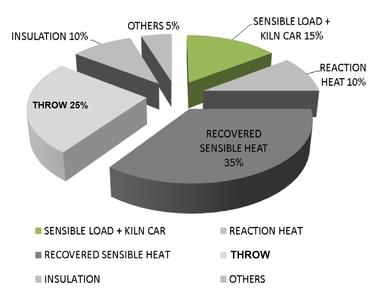

Given the fact that 1 kg of air and 1 kg of clay/shale have about the same specific heat (0.24 and 0.22 kcal/kg/C respectively), one could conclude that a perfect tunnel kiln is where about 1 kg of air travelling one way will suffice to heat and cool 1 kg of product travelling in counter flow to the air.

In reality, this ratio in tunnel kilns varies from 2 to 4.5 kg/air per kg of fired...