CO2-neutral air conditioning

One cause of the increasing CO2 emissions lies in the environment-impacting air conditioning of buildings with Air Conditioning Systems (ACS), the start-up EcoClima is convinced of this. According to the founders, they have developed a CO2-neutral-working system with which, in comparison with ACS, over 90 % of operating costs can be saved and a healthy, comfortable indoor climate guaranteed. The air conditioning elements from EcoClima enabled cooling even below dewpoint and are therefore especially suitable for use in regions with a high cooling requirement, says the start-up.

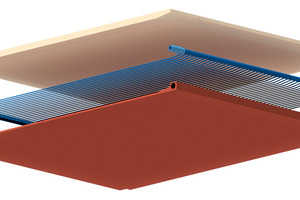

The product consists of three layers: a calcium-silicate board that absorbs moisture (condensate), but can also give this moisture off again. A homogeneous, pleasant relative air humidity of 40 – 60 % is guaranteed. Below this lies a capillary tube mat, which enables surface heating and cooling in the low-temperature range. The third layer consists of clay plaster and clay paint that absorb pollutants and odorants from the air and is reported to ensure a healthy indoor climate. The founders see other advantages in the system’s zero maintenance requirement as no filters have to be changed and no burners adjusted. For this reason, they say that the system is also user-friendly as only simple control and regulation technology is necessary. Moreover, they say that the EcoClima system can be recycled.

Sales and production concept

The system is to be manufactured where the air conditioning elements are installed. In this way, the founders aim to minimize the CO2 footprint, and, at the same time, added value is to be generated and jobs created in the target regions.

Between the local producers, ideally brick plants, and the start-up, supply contracts are to be agreed. EcoClima will supply machinery, processing and installation guidelines and arrange training as well as marketing and advertising. The local partner will be in charge of the manufacturing and effective sale of the system locally. According to EcoClima, the system has already been tested successfully at the University of the Balearic Islands.

The start-up is now looking for partners worldwide, ideally brick plants. With the Association of the Spanish Brick Industry, a presentation has been arranged for summer 2022 to which all 84 association members are invited. The start-up founders hope that the first licence agreements can be concluded with some of the conference delegates.

The start-up is still in the founding phase. Under EP 3 146 271, a patent has been filed for the system at the European Patent Office. Anyone interested can contact the founders by telephone +49 176 41 09 66 33 or +49 30 23 94 95 82 or by email to .