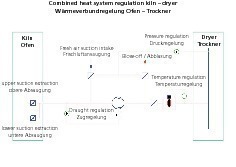

The role of the combined heat system

in the brick plant

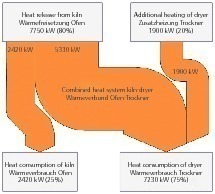

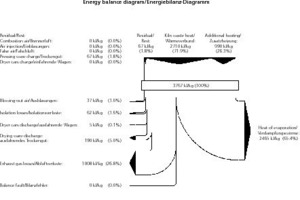

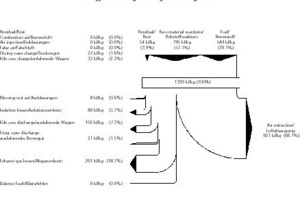

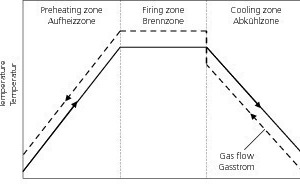

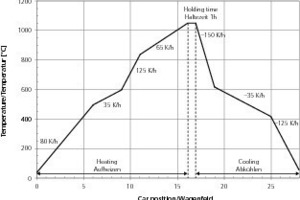

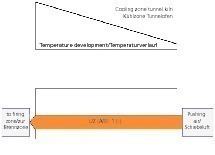

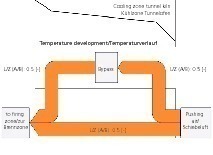

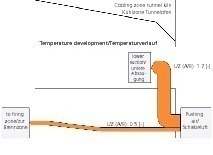

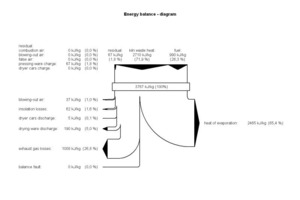

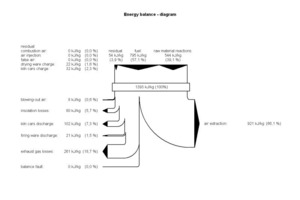

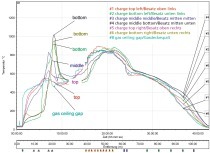

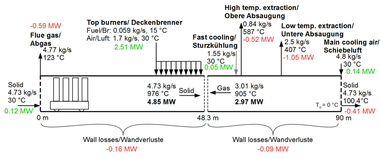

This article describes the influence of the combined heat system on the dryer and kiln operations and demonstrates how the release of cooling heat from tunnel kilns can be reduced. In order to illustrate the possibilities for lowering the release of cooling heat from the kilns, above all in regard to the use of low-energy dryers, the paper outlines not only the historical development of the installations in the cooling zone but also their influence on the kiln operations and the heat release of the kiln. Furthermore the theoretical explanations on kiln operation without the combined heat system are supplemented by examples for optimum practical implementation in terms of technical equipment. Here the paper distinguishes between kilns with small and large raw material enthalpies.

1 Introduction

The combined heat system between the kiln and dryer was already used in individual cases at the beginning of the 20th century in large-volume dryers arranged above the annular kiln (1903, fan heating at the Brüggener Tonwerke [18]). It was only from the 1950s onward that the combined heat system experienced a wider distribution, above all in the German-speaking countries, with the introduction of the tunnel kiln and artificial drying. In other countries (for example in France) there is even today still a large number of brick plants which do not have a combined heat system...