Improving the quality of cut and reducing energy

expenditures for brick production by use of vibrating

cutters with piezoelectric and electroosmotic drives

1 Background

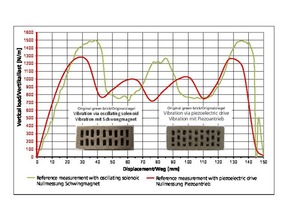

The vibration cutting technique employing an oscillating solenoid, as already investigated in project AiF 16074 N, enables achievement of a cleaner quality of cut coupled in most cases with less force required of the cutting wire. However, interference affecting the cutting wire often causes choppy cuts. Moreover, the vibration technique, with its oscillating solenoid, is both bulky and loud.

2 Objective

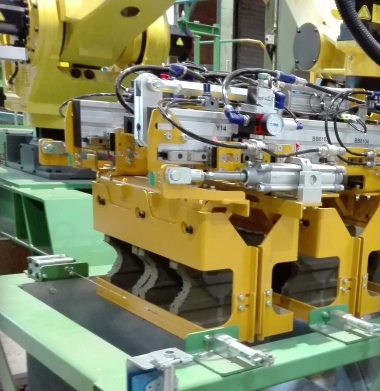

A piezoelectric drive of the kind now normally used in high-precision mechanics was supposed to solve the familiar problems and enable clean cutting of vertically perforated clay...